Aliplast aluminium

Aliplast aluminium – strength, style and comfort for modern architecture

Aliplast aluminum systems are a robust and aesthetically pleasing solution for modern homes and buildings. They insulate perfectly, are resistant to weather conditions and allow the creation of large glazing. It's comfort, durability and style all in one.

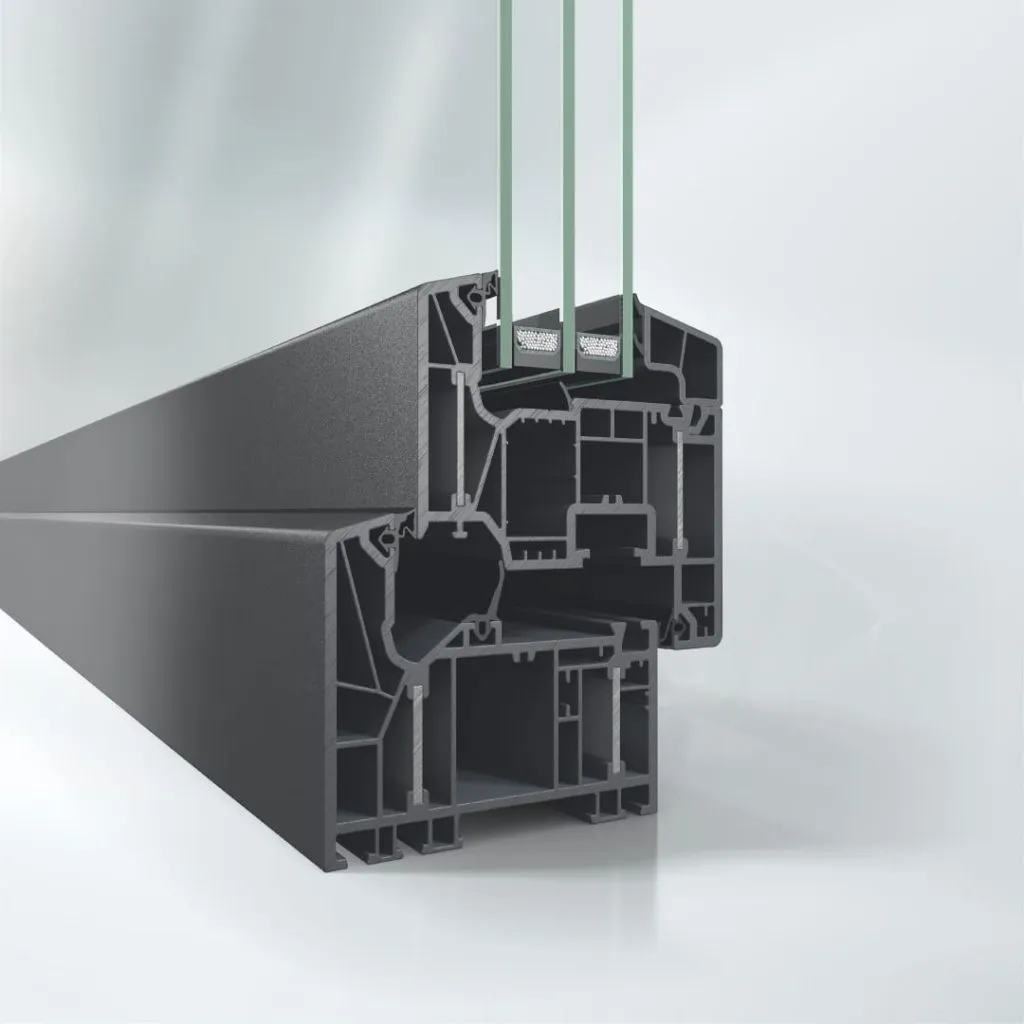

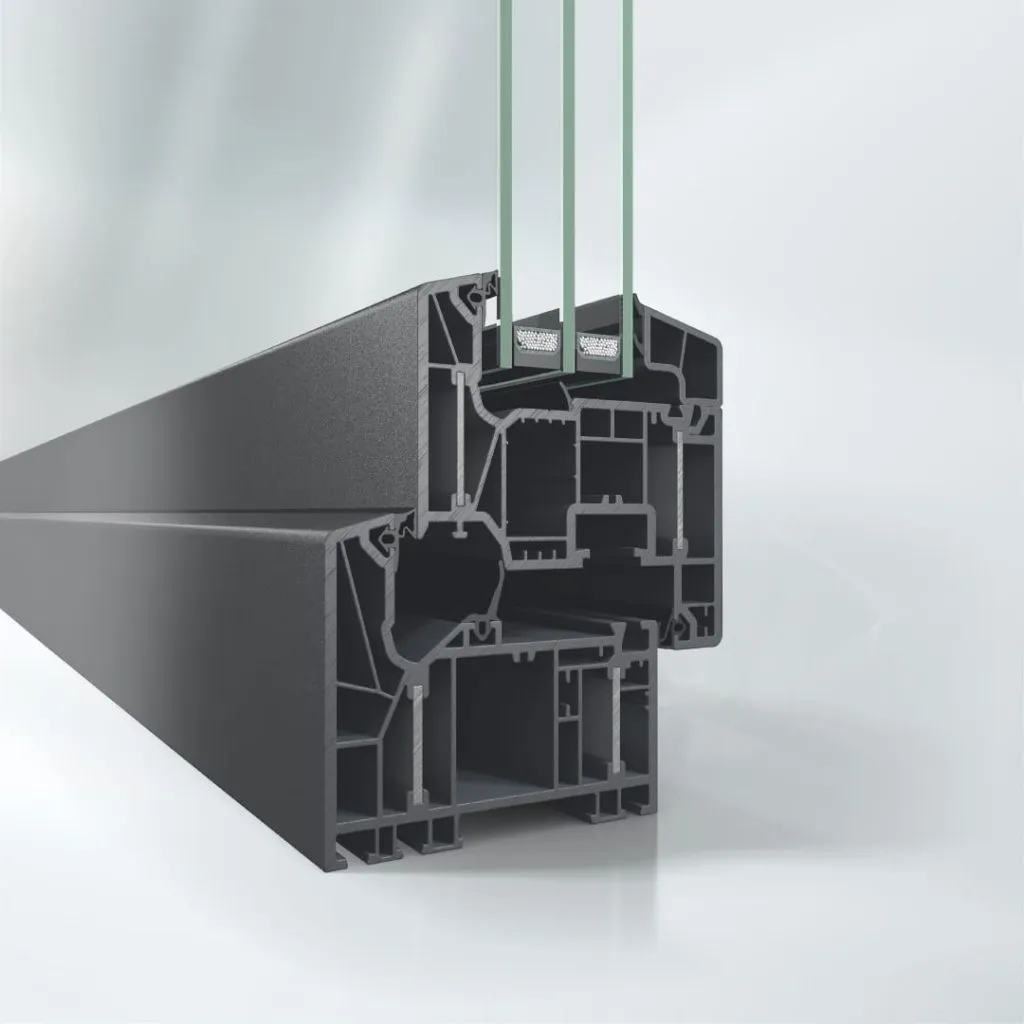

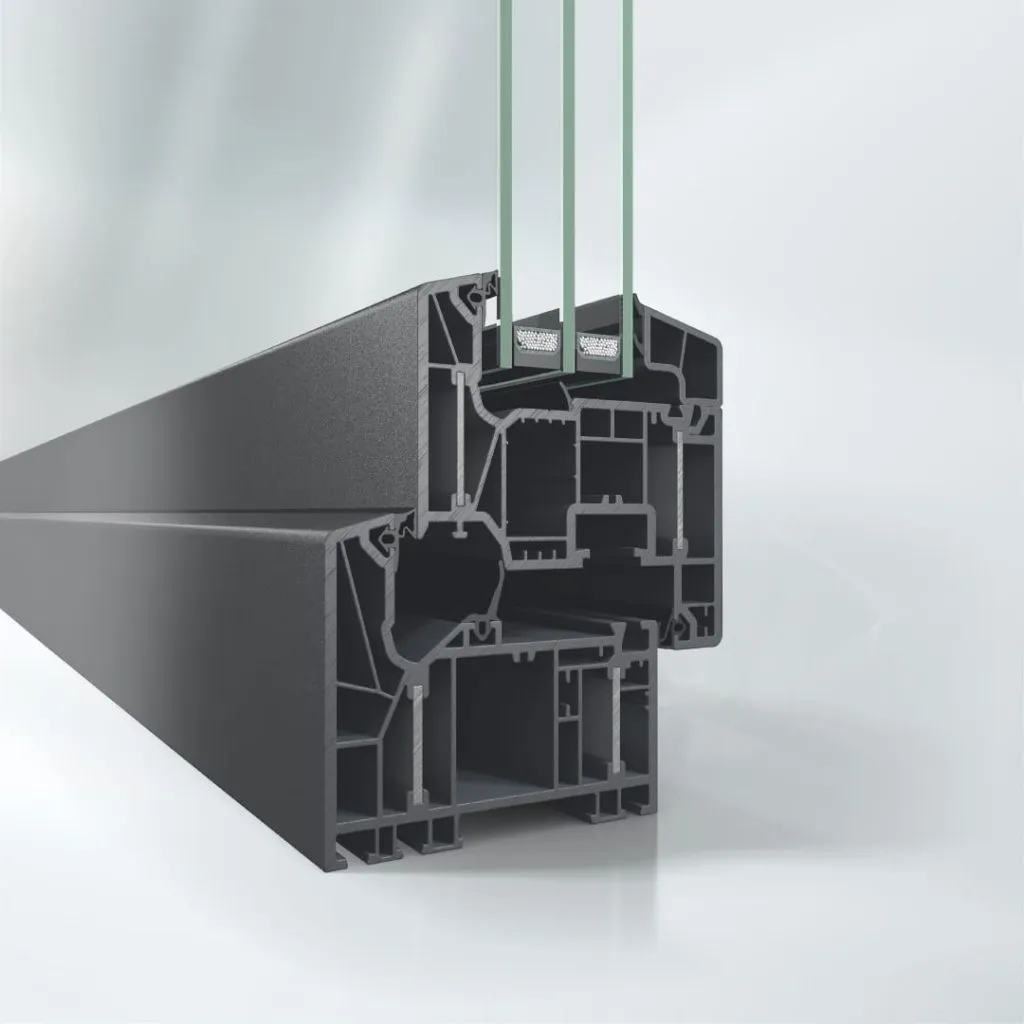

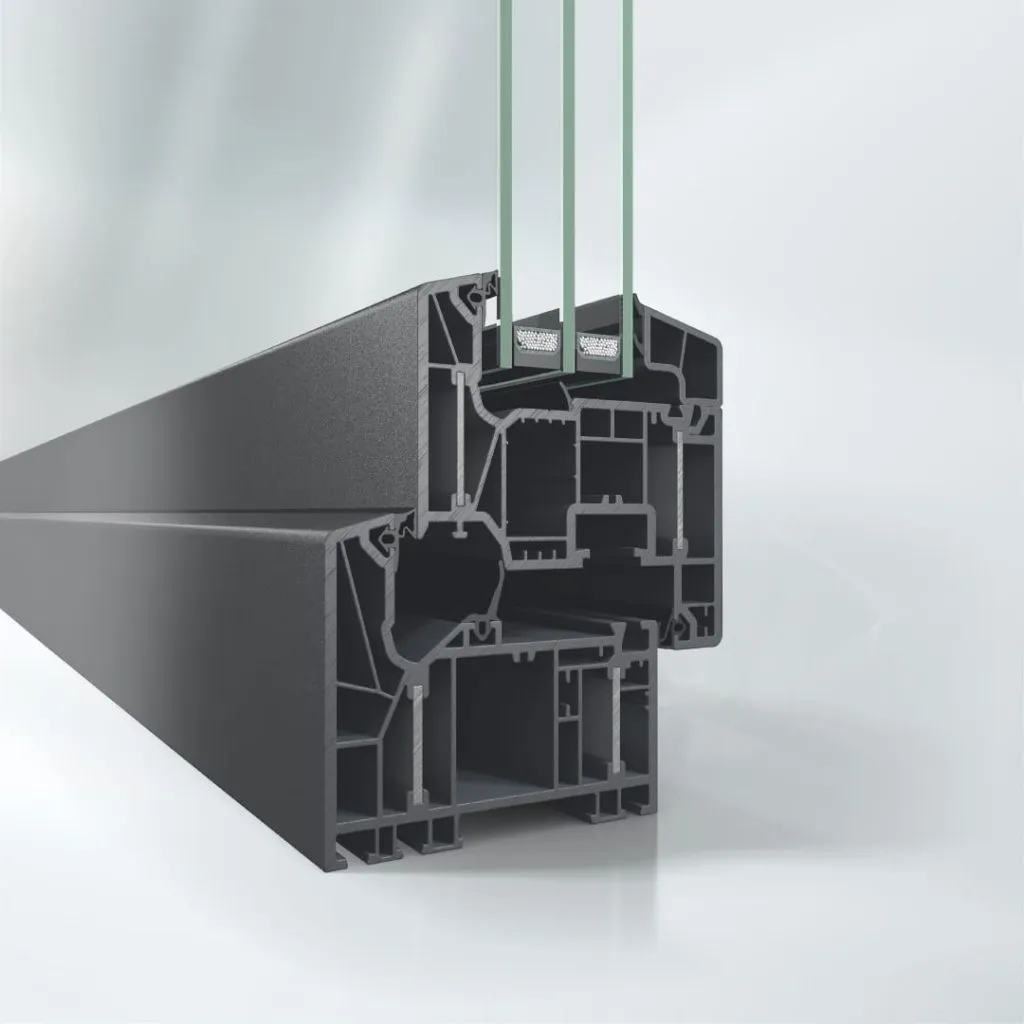

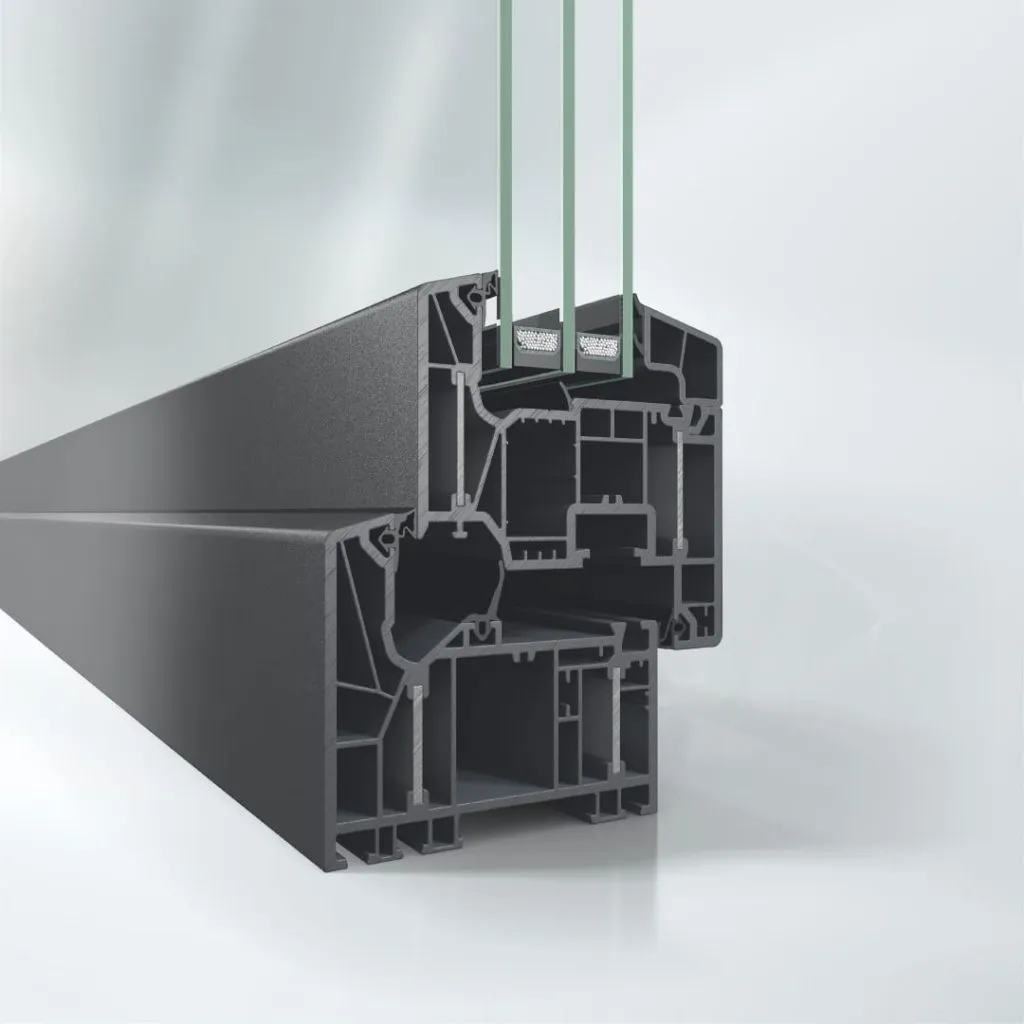

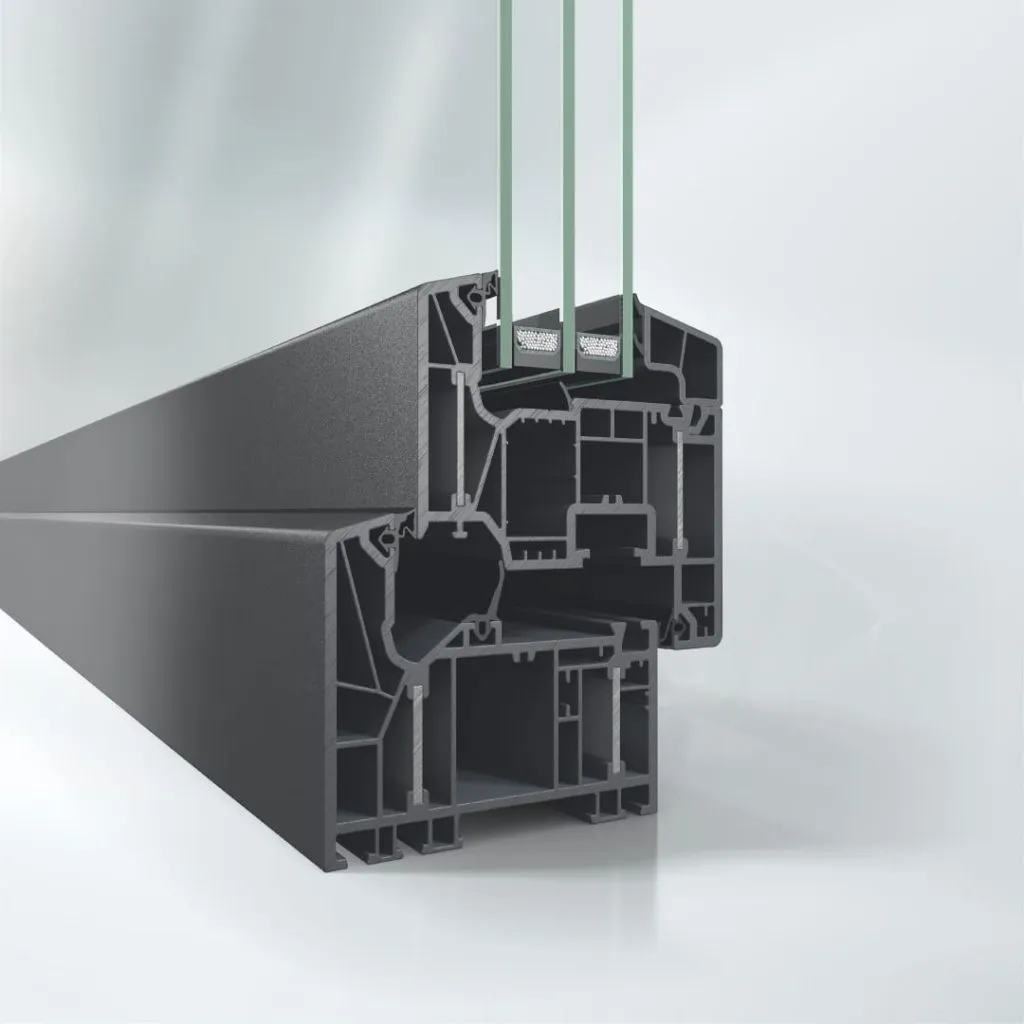

Aliplast Star

- A modern aluminum system for designing windows and doors that require excellent thermal insulation.

- A 1.77-inch deep thermal break, made from durable and proven materials, provides a reliable thermal barrier.

- The same type of insulation insert in both the window sash and frame ensures continuous heat loss protection throughout the structure.

- A new standard for profile-to-glass overlap – increased depth improves the system's thermal and structural properties.

- Option to equip doors with a high-load-bearing roller hinge system.

- Innovative water drainage system (no visible drainage hole covers).

- Possibility of external glazing.

- Modern design.

- The system is particularly recommended for low-energy buildings and thermal modernization projects, enhancing thermal comfort even in standard structures.

- FRAME DEPTH – 3.54 in

- GLAZING THICKNESS – Fix 0.55-2.83 in / 0.91-3.19 in

- THERMAL INSULATION UF* – Uf from 0.129 BTU/(h·ft²·°F)

- AIR PERMEABILITY – Class 4; standard PN-EN 12207

- WIND LOAD RESISTANCE – Class C5; PN-EN 12210

- WATER TIGHTNESS – Class E900; PN-EN 12208

Aliplast Star – door panel

- A thermally insulated aluminum system designed for panel doors. Thanks to modern technical solutions, panel doors can be not only a functional and durable entrance to a home but also a decorative and stylish feature.

- The system offers a wide range of filling panels available in various designs and colors. The elegant appearance of the structure, available sizes, and the possibility of integrating doors into larger glass façades provide great flexibility in designing building entrances.

- The structural framework of the panel door system is based on the STAR system, ensuring excellent thermal insulation. This directly impacts both indoor comfort and overall energy efficiency, reducing operational costs.

- System Features:

- A single plane for the door frame and the panel bonded to the sash (panel applied on the exterior side or on both sides).

- Two hinge options: a roller hinge dedicated to the STAR system or a concealed hinge (Dr. Hahn).

- FRAME DEPTH – 3.54 in

- FILLING THICKNESS – Single-sided panel: 0.87-3.27 in / Double-sided panel: 3.54 in

- THERMAL INSULATION UF* – Uf from 0.129 BTU/(h·ft²·°F)

- AIR PERMEABILITY – Class 4; standard PN-EN 12207

- WIND LOAD RESISTANCE – E2400; EN 12210

- WATER TIGHTNESS – 7A (43.53 psi); EN 12208

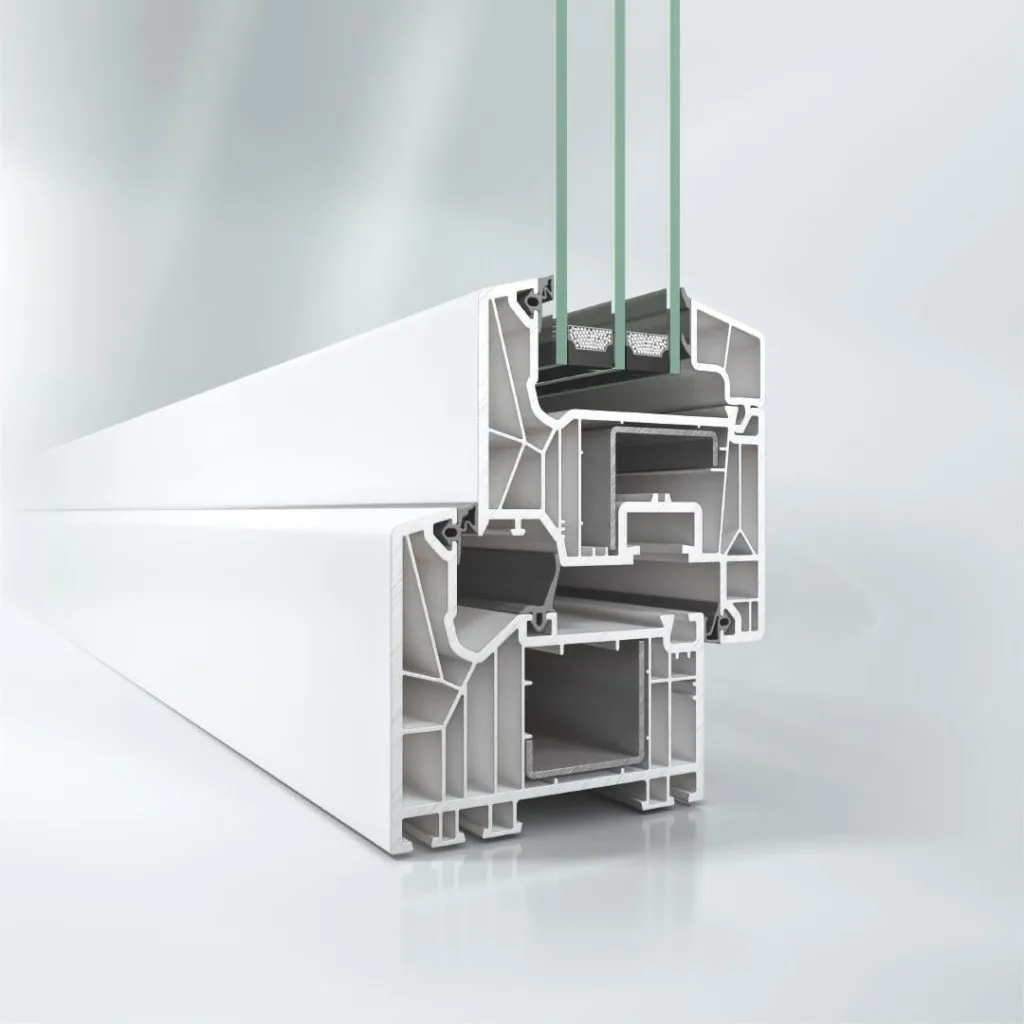

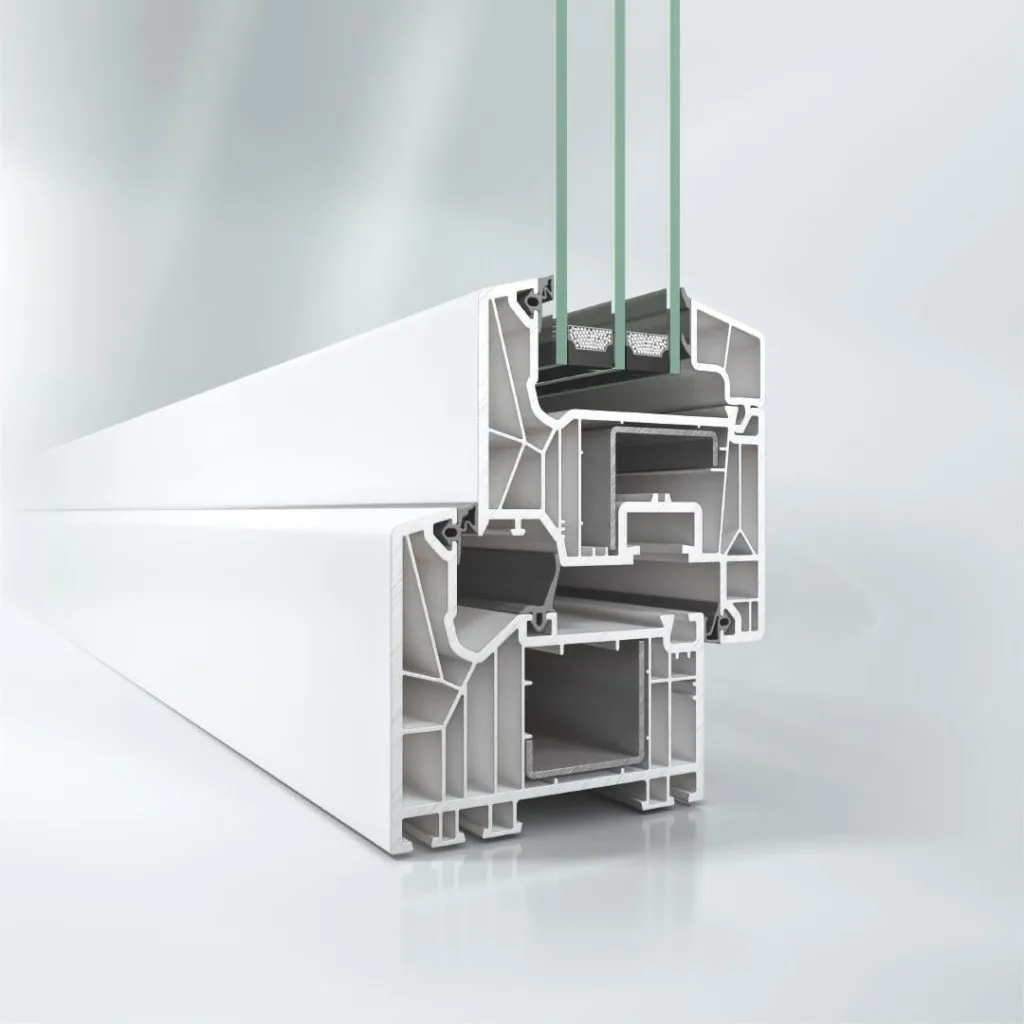

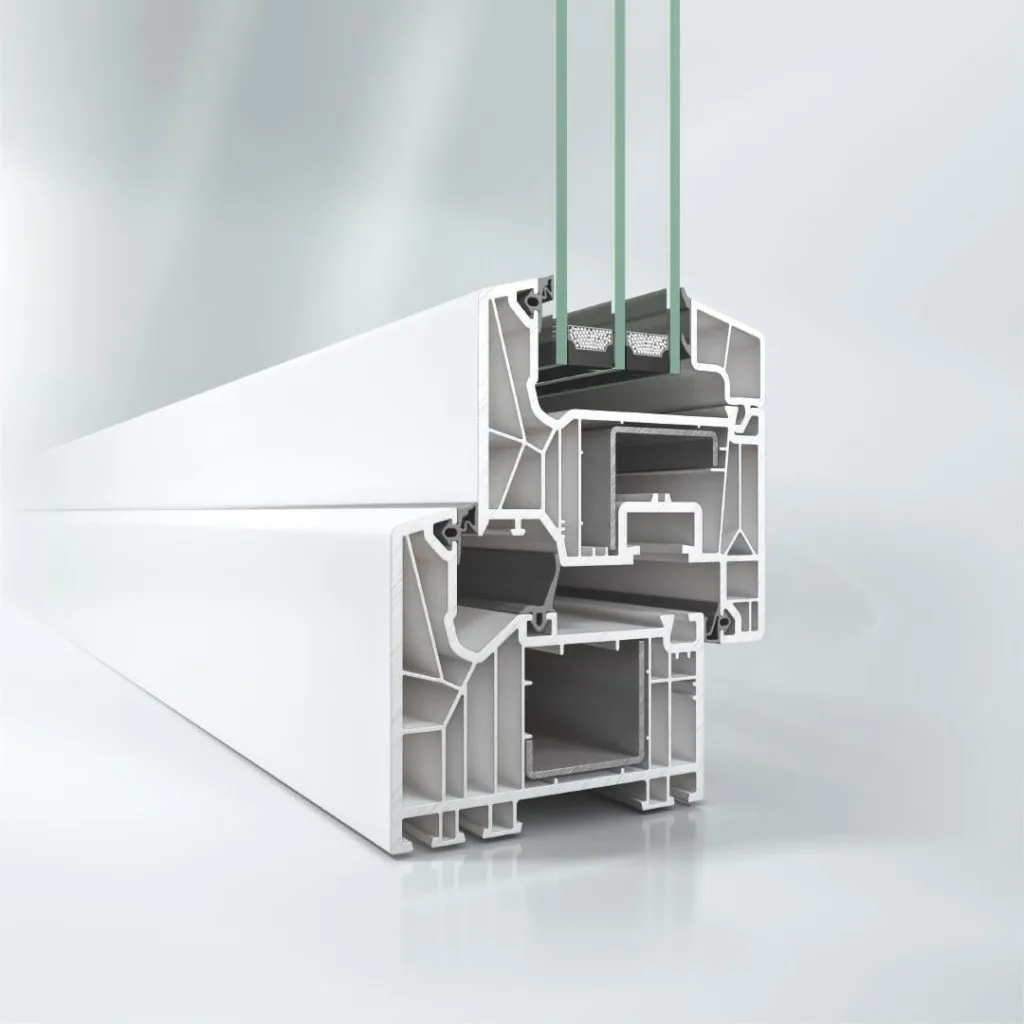

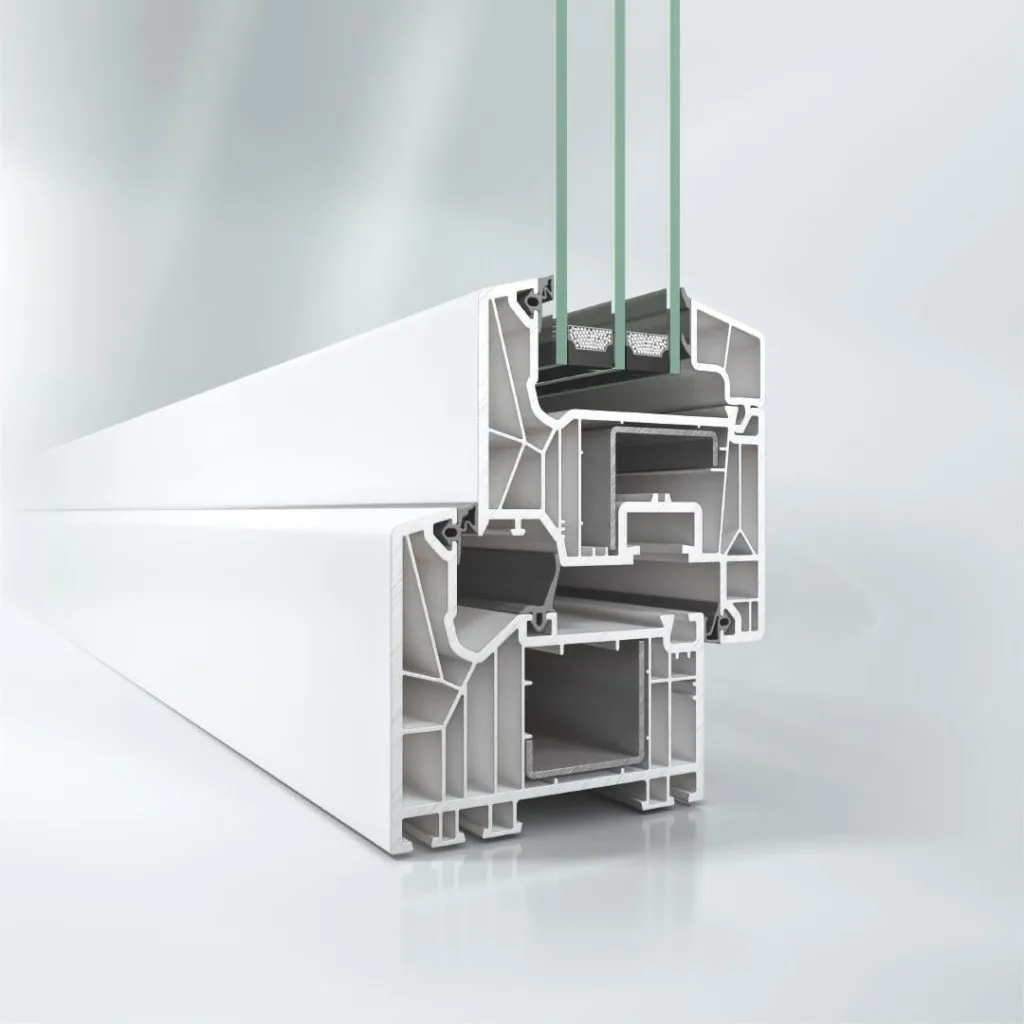

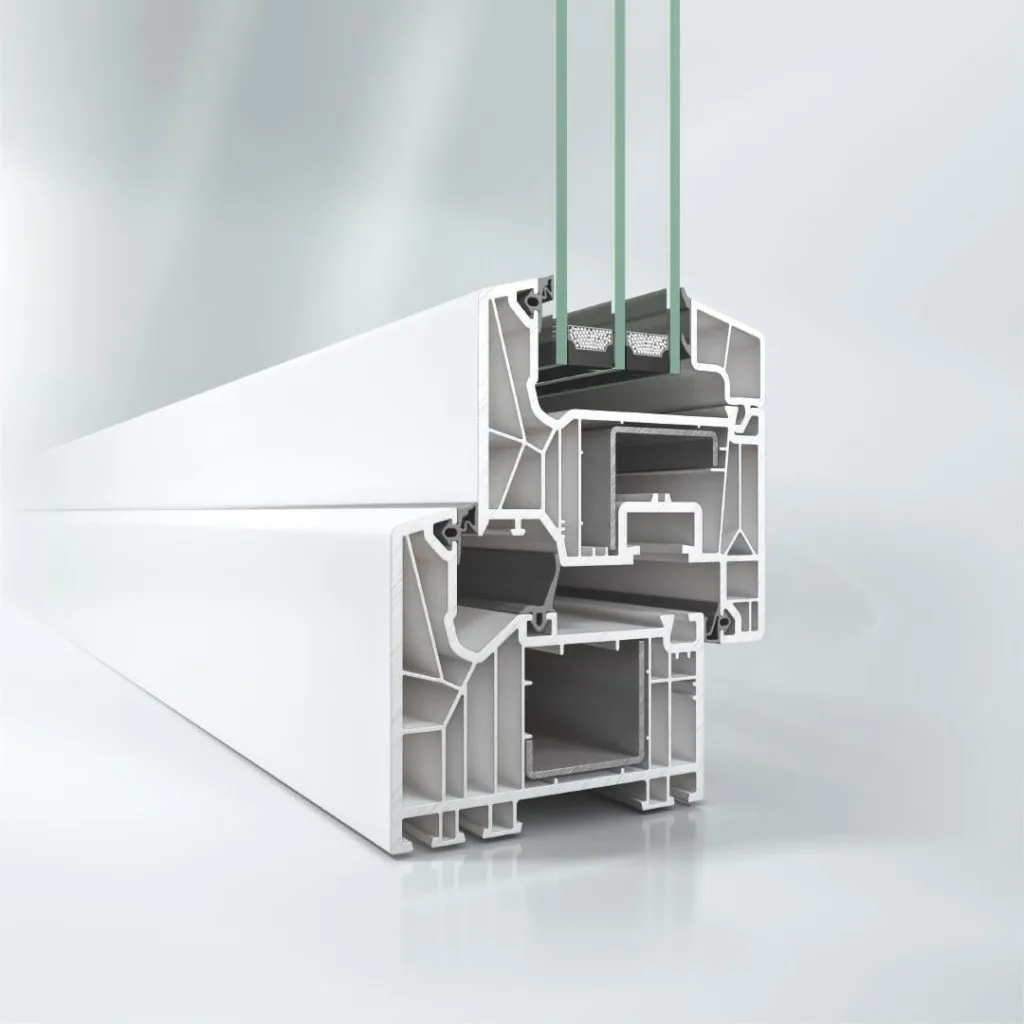

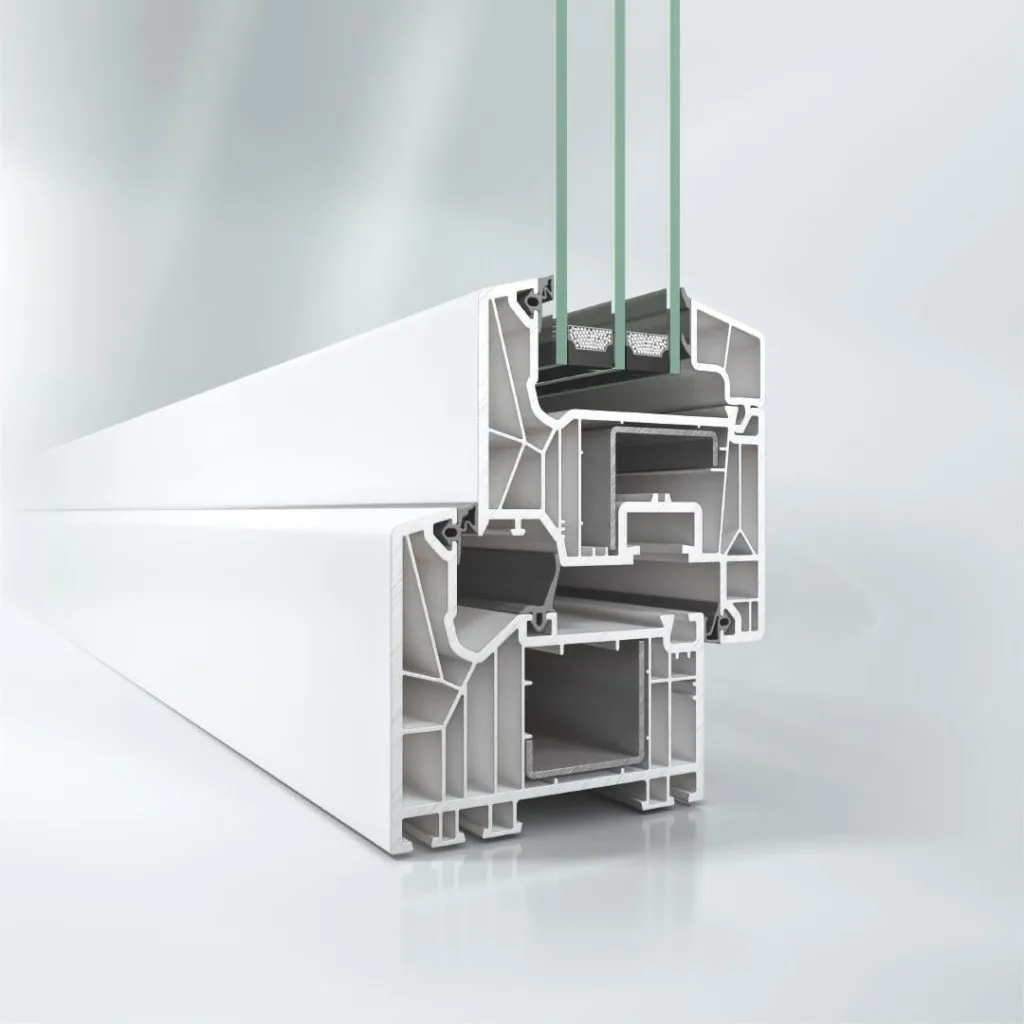

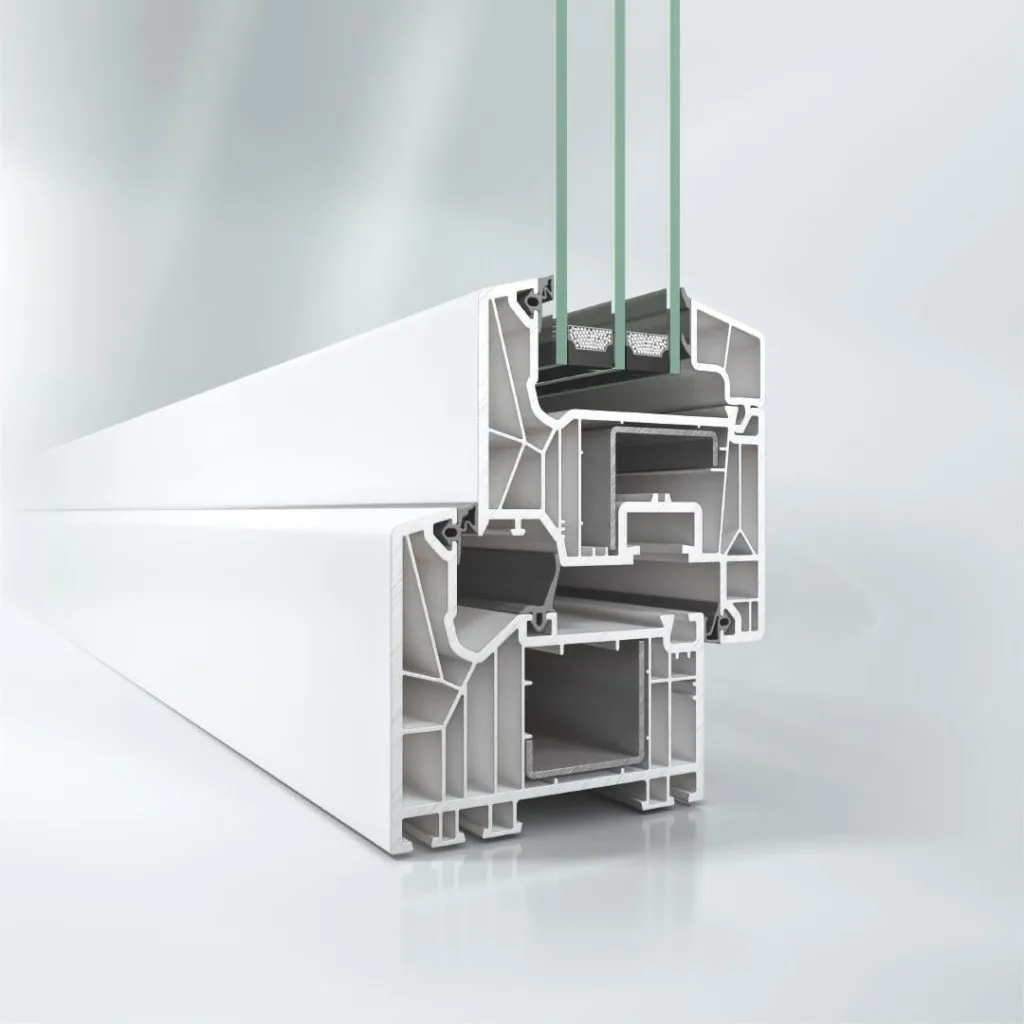

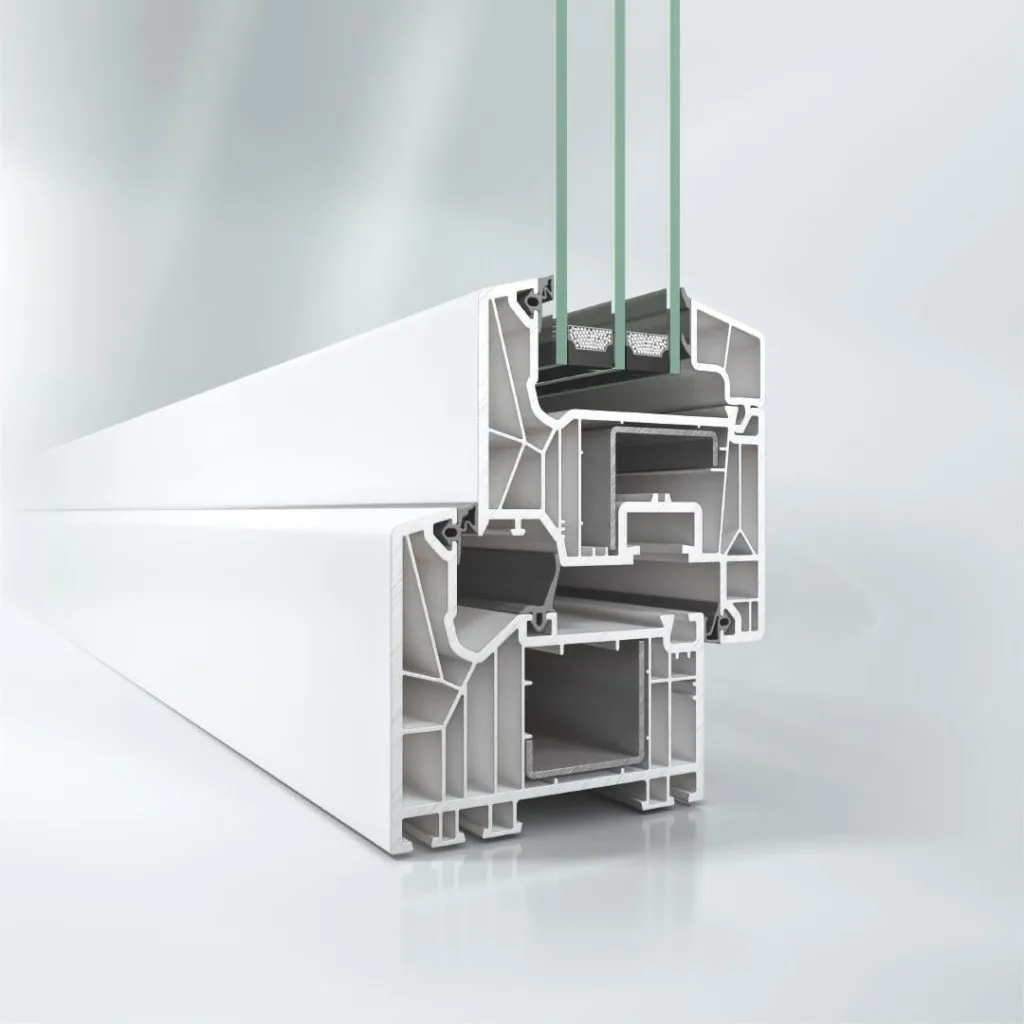

Aliplast Genesis

- A three-chamber window and door system designed for windows with enhanced thermal insulation.

- The thermal performance of Genesis 75 windows meets the requirements effective from 2021 (Uw from 0.90).

- The core of the Genesis 75 system consists of frame profiles with a depth of 75 mm.

- The wide range of profiles available in the Genesis 75 system allows for the design of modern windows, doors, and facades with high functionality.

- The Genesis 75 system features advanced insulating materials, a novelty in the market. In addition to the classic central window gasket, an additional thermal gasket has been designed. This solution ensures excellent airtightness (air infiltration and water tightness) while offering a modern appearance and aesthetics.

- The system offers various profile finishes (including renovation profiles), allowing for a customized window design.

- Enables fully glazed 90-degree corner connections.

- The Genesis 75 window and door system sets a new standard for window insulation while maintaining superior user ergonomics and modern profile aesthetics.

- Available Genesis OUT options (Genesis OUT i, Genesis OUT i+) – outward-opening windows.

- The Genesis 75 door system can also be used to create panel doors.

- Genesis 75 is designed for window and door structures in both public buildings and single- or multi-family residential developments.

- FRAME DEPTH – 2.95 in

- GLAZING THICKNESS – fix 1: 0.04-2.20 in / 0.35-2.56 in

- THERMAL INSULATION UF* – Uf from 0.148 BTU/(h·ft²·°F)

- AIR PERMEABILITY – Class 4; standard PN-EN 12207

- WIND LOAD RESISTANCE – Class C4 (34.81 psi); PN-EN 12210

- WATER TIGHTNESS – E1800 (261.07 psi) / E1950* (282.89 psi); PN-EN 12208

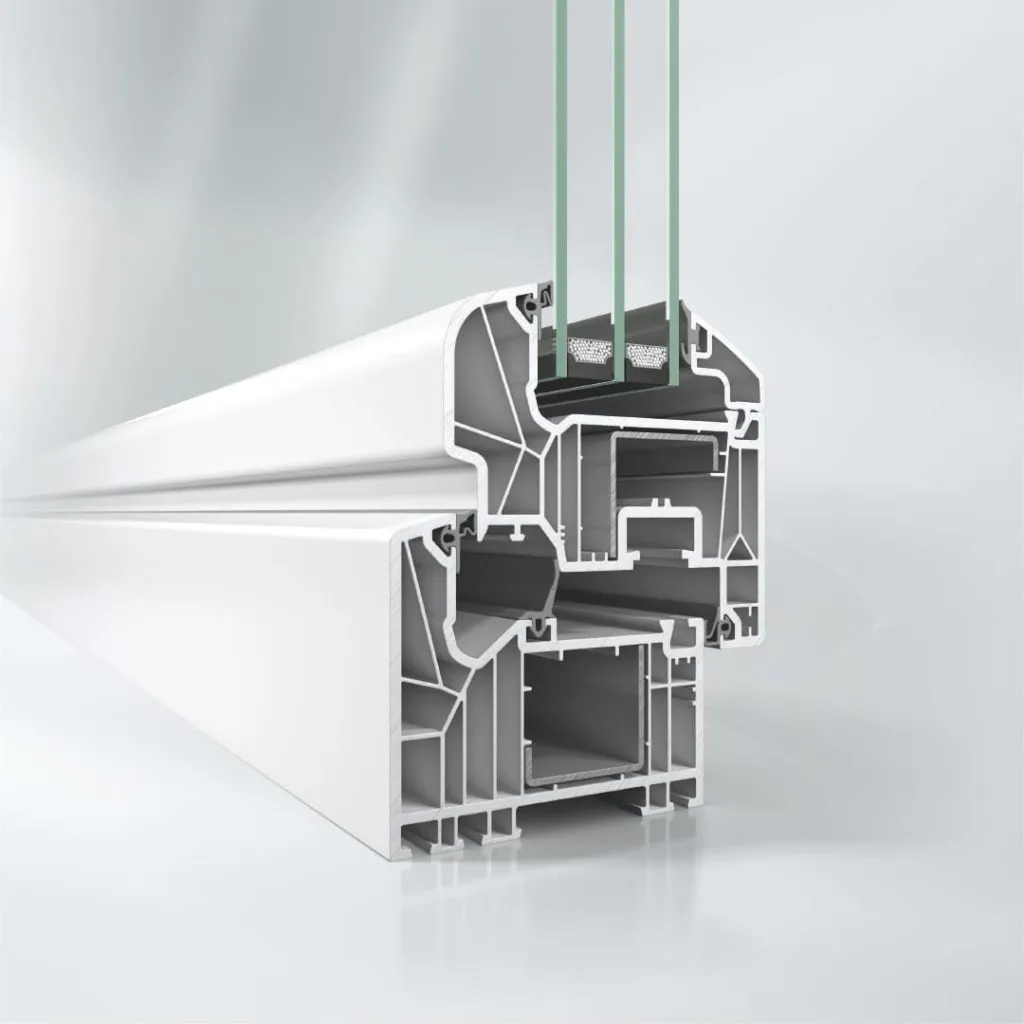

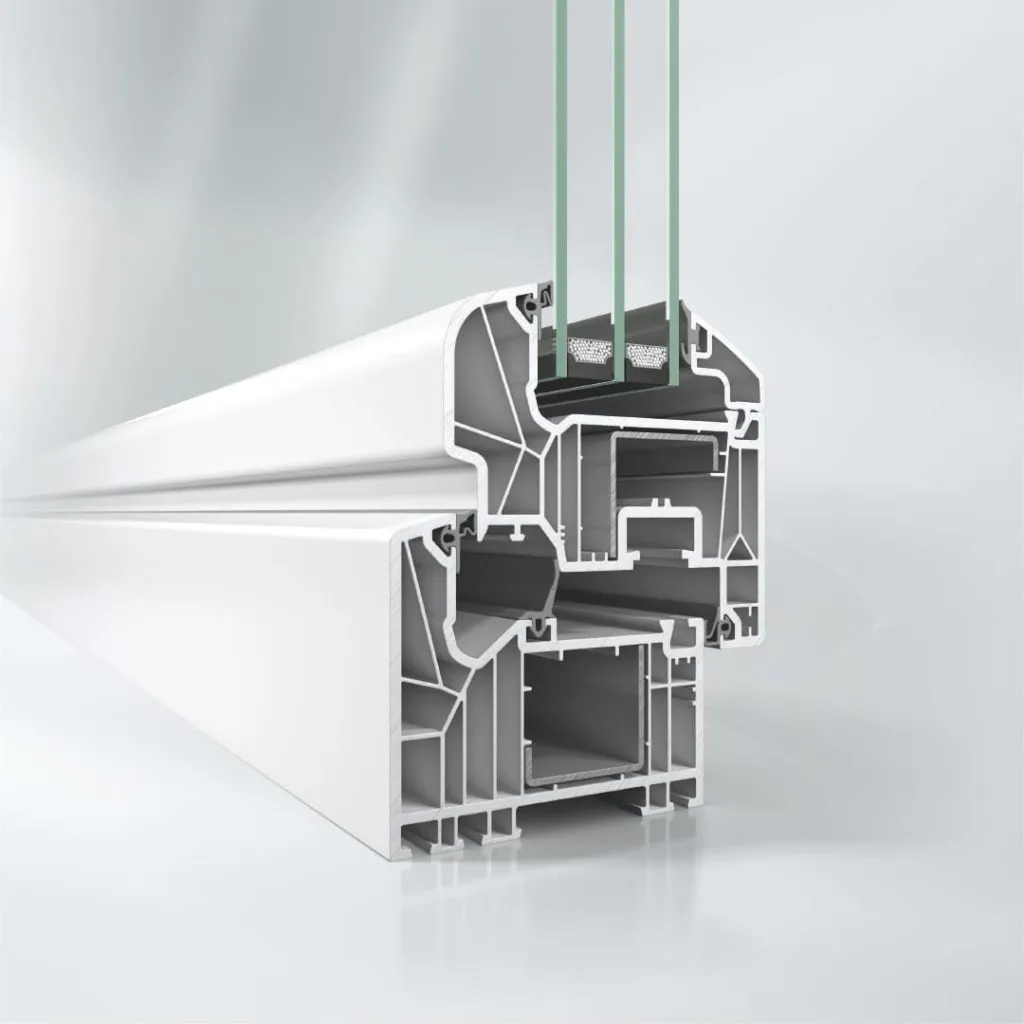

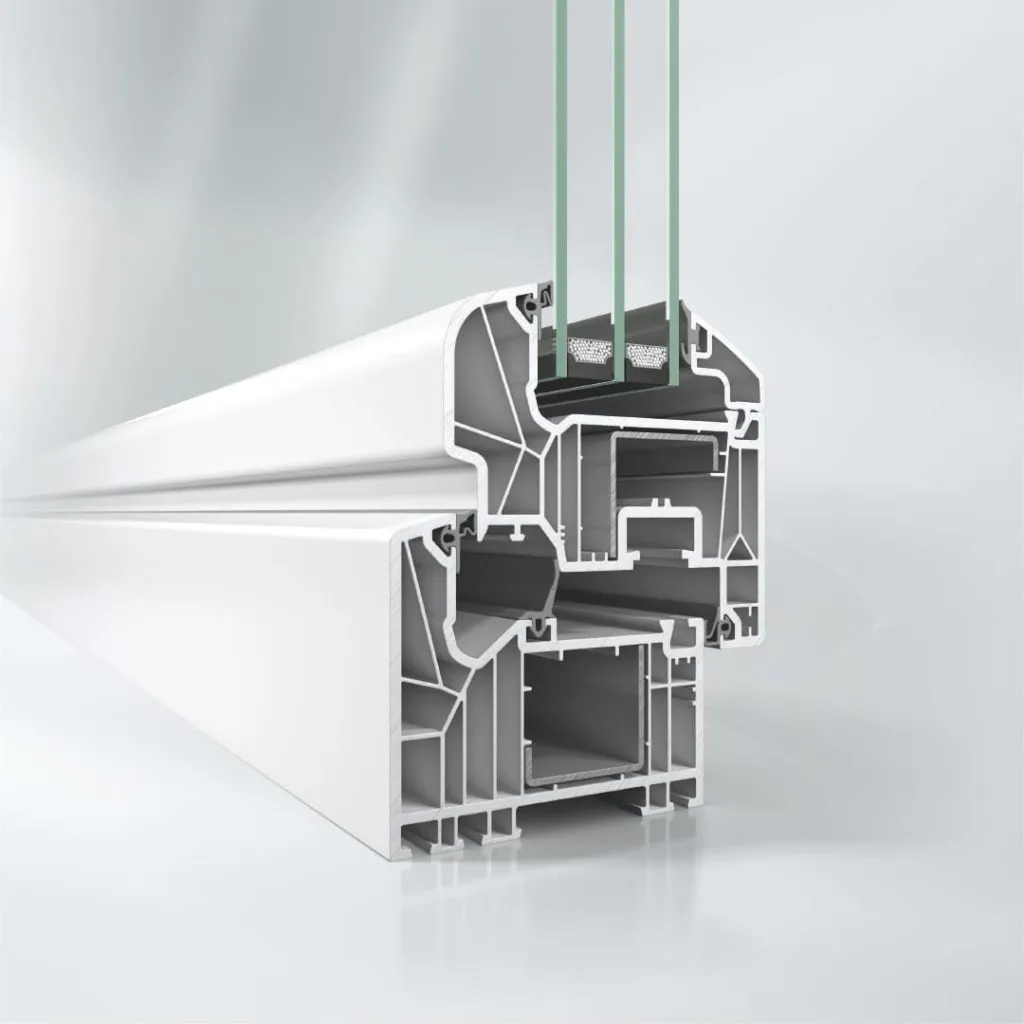

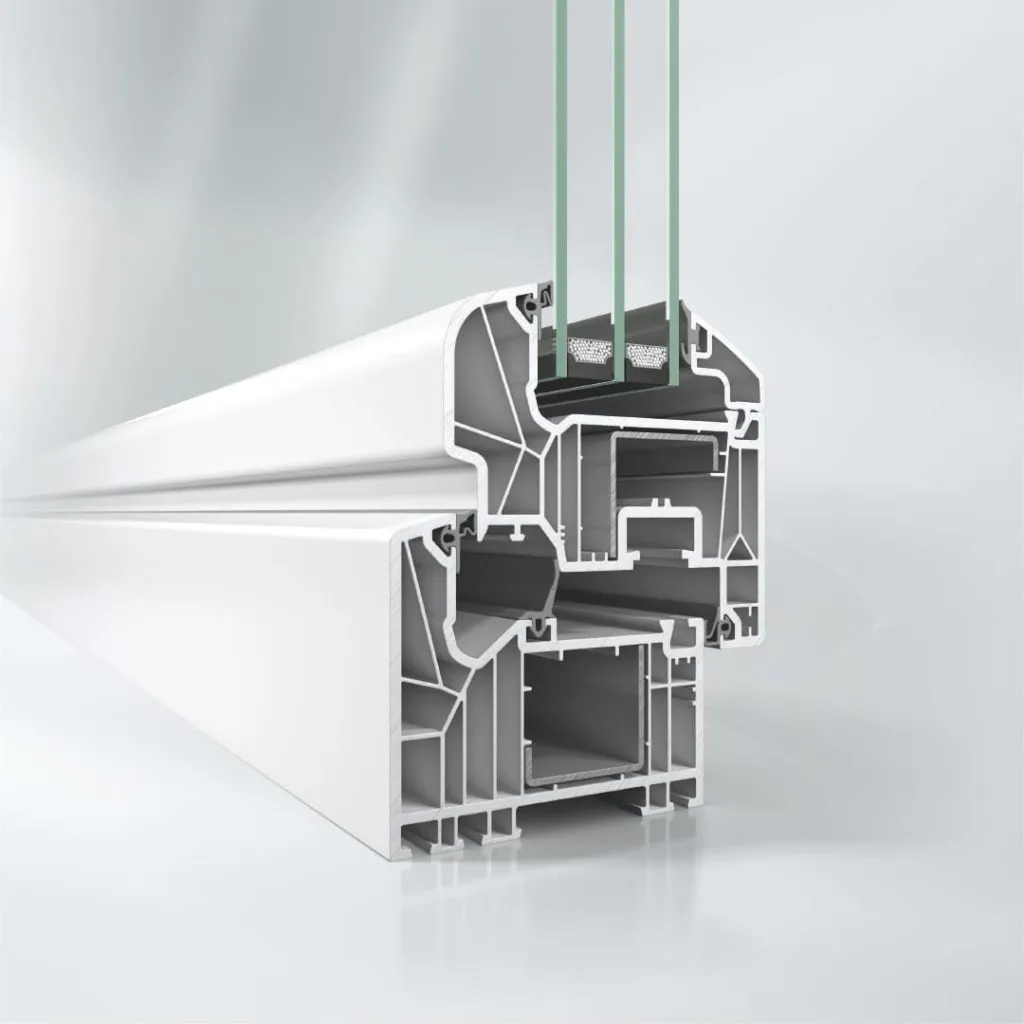

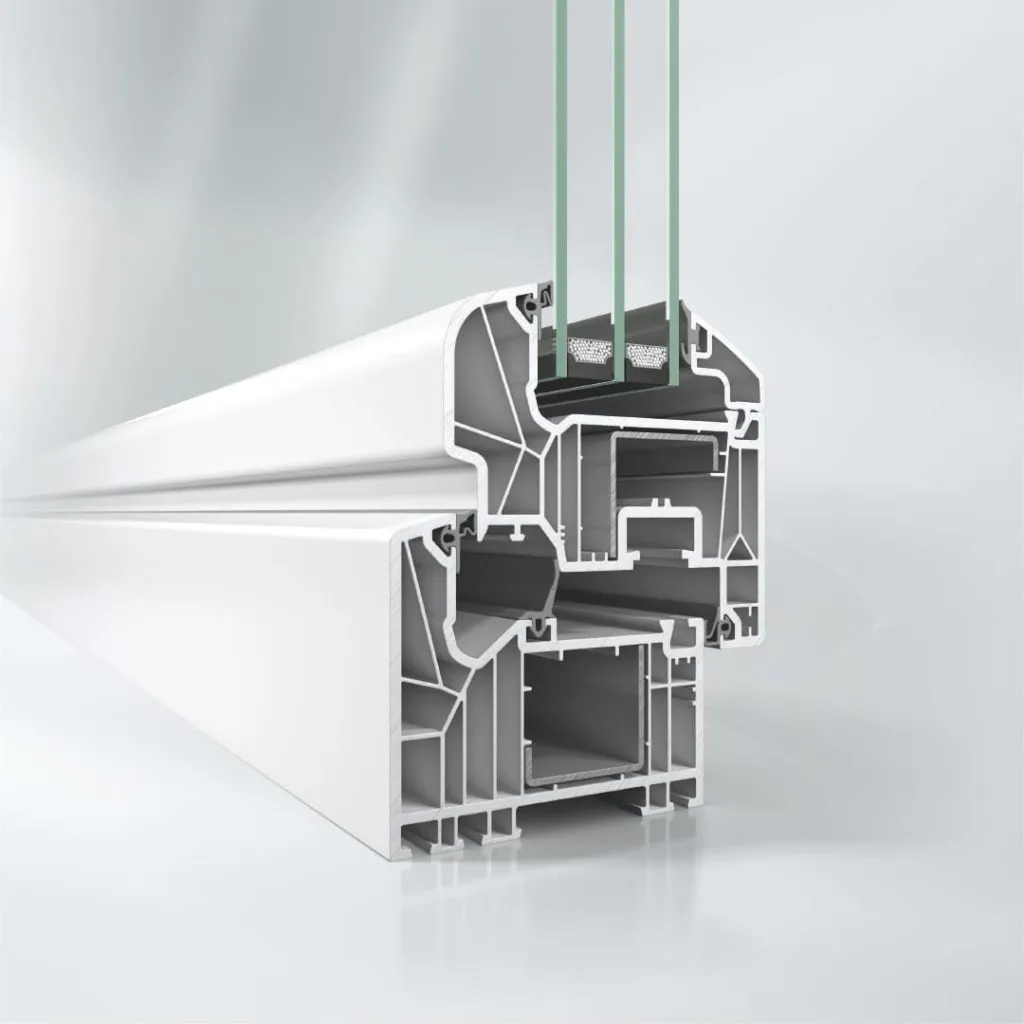

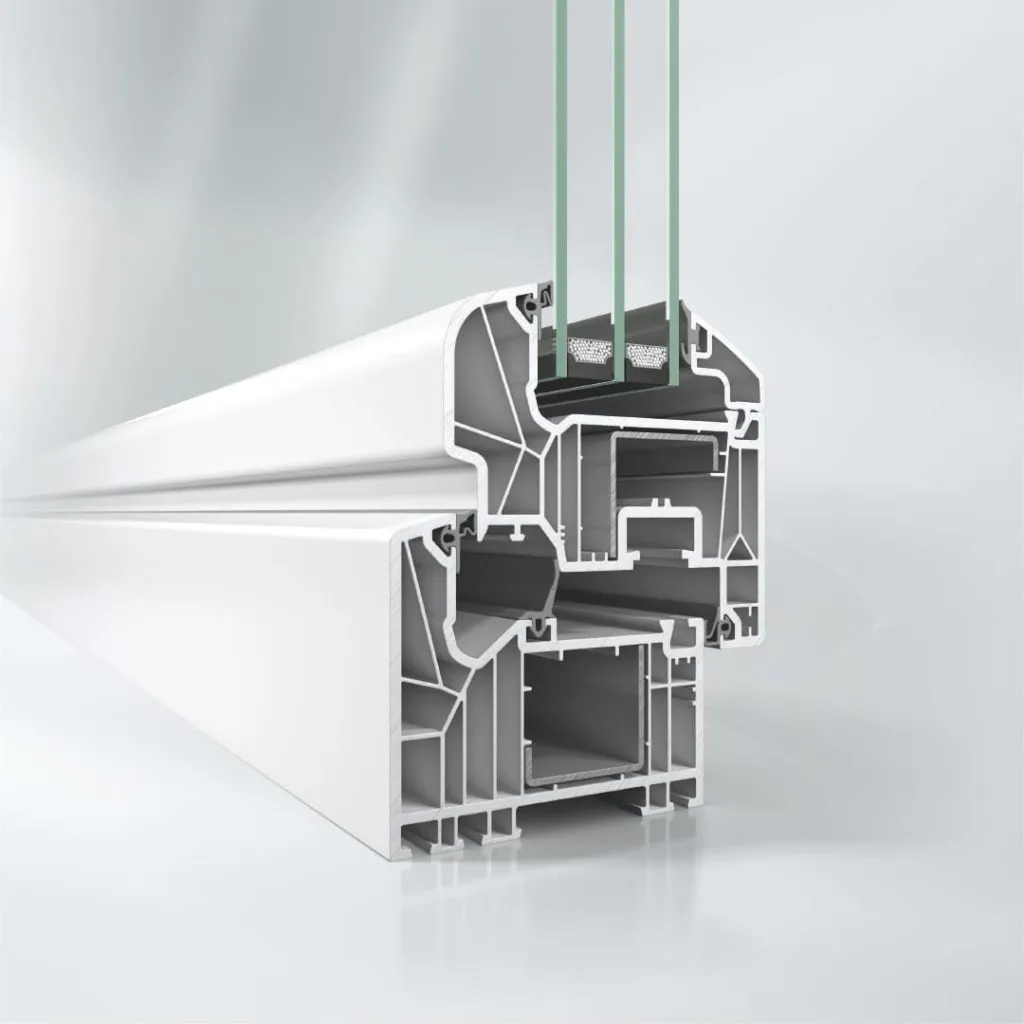

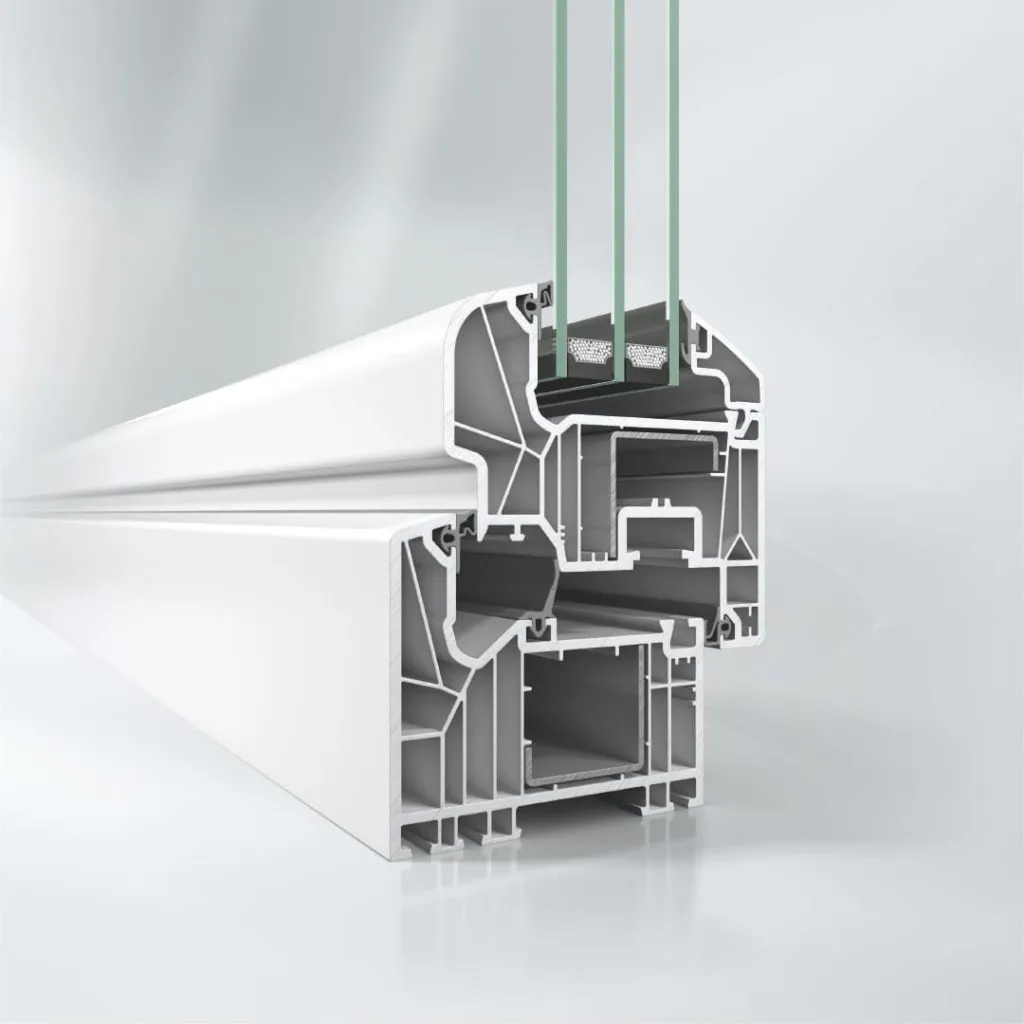

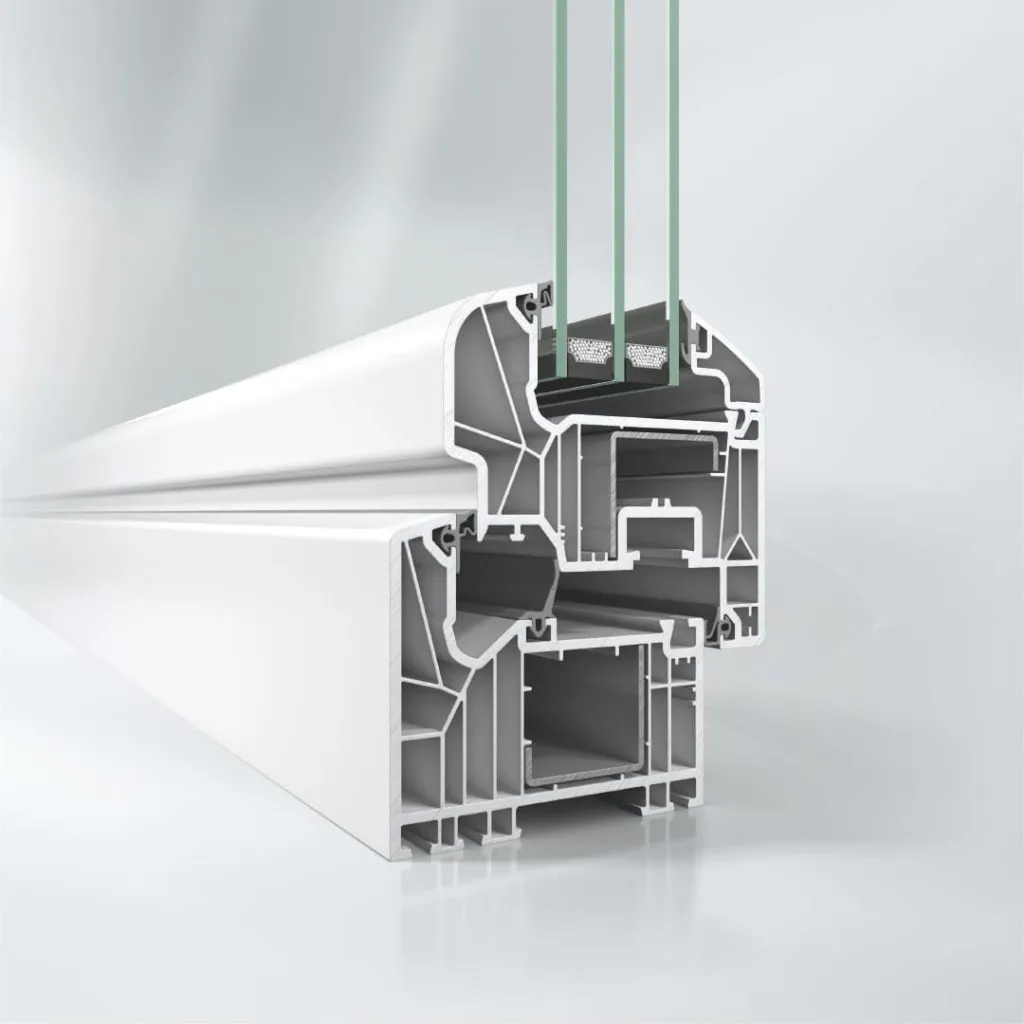

Aliplast Superial

- A system designed for constructing windows, doors, and storefronts with high thermal insulation performance.

- High thermal insulation parameters are achieved through the use of special thermal inserts placed between thermal breaks and around the glass, improving sectional insulation by 0.2-0.4 W/m²K.

- A wide range of profiles ensures the required aesthetics and structural durability.

- Windows can be installed within façade systems.

- Glazing beads available in rectangular and rounded variants.

- The broad glazing range allows for the use of all common glass types: single, double-chamber, acoustic, or burglar-resistant.

- Profile drainage is available in two options: traditional or concealed.

- A low-threshold option is available for single and double-leaf balcony doors with rectangular profiles (structures using dedicated profiles); additionally, the sealing performance of the structure can be enhanced with the ACRS461 gasket.

- The system enables the design of modern window solutions in various configurations, making it suitable for residential and public utility buildings.

- The construction of the SPi and SPi+ systems is based on the proven, well-developed, and highly regarded Superial base system.

- FRAME DEPTH – 2.95 in

- GLAZING THICKNESS – 0.55-2.40 in

- THERMAL INSULATION UF* – Uf from 0.248 BTU/(h·ft²·°F)

- AIR PERMEABILITY – Class 4; standard PL-EN 12207

- WIND LOAD RESISTANCE – Class C5/B5; standard PL-EN 12210

- WATER TIGHTNESS – Class E1950; standard PL-EN 12208

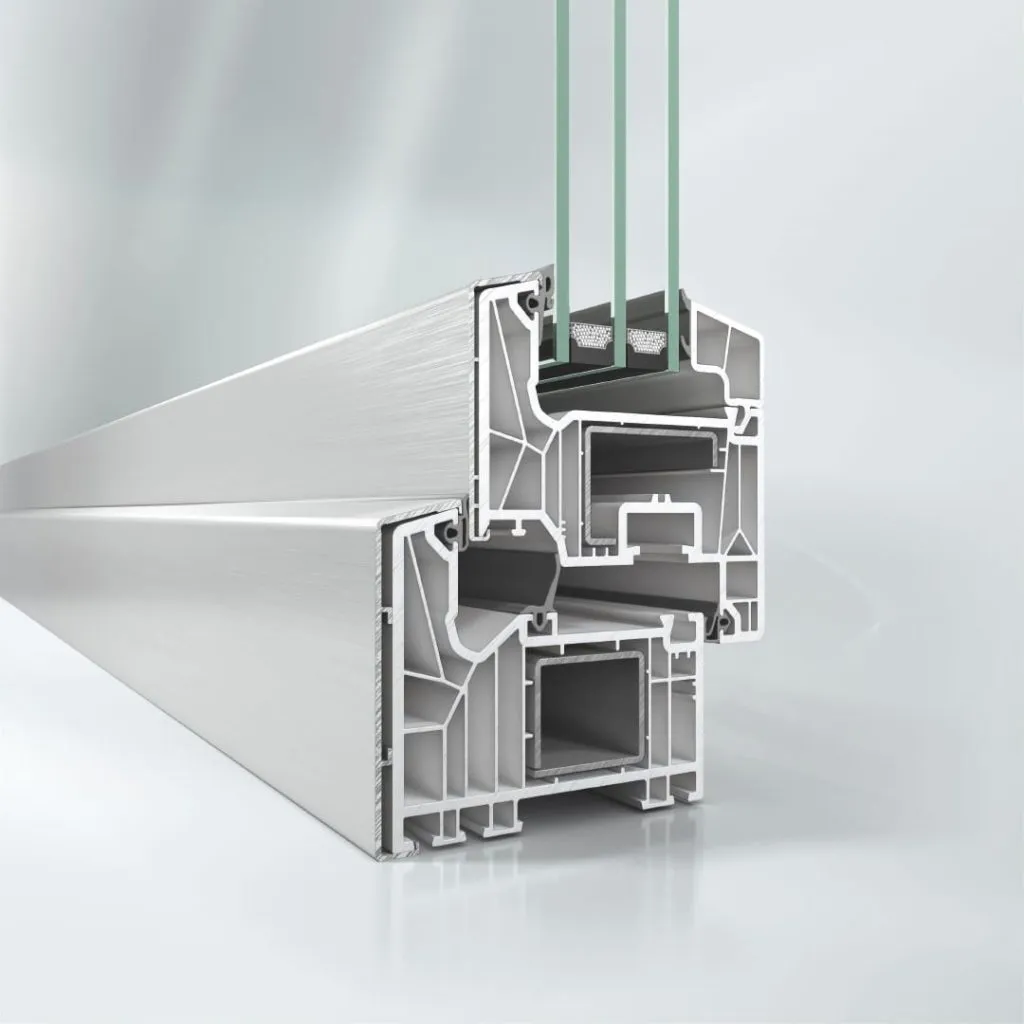

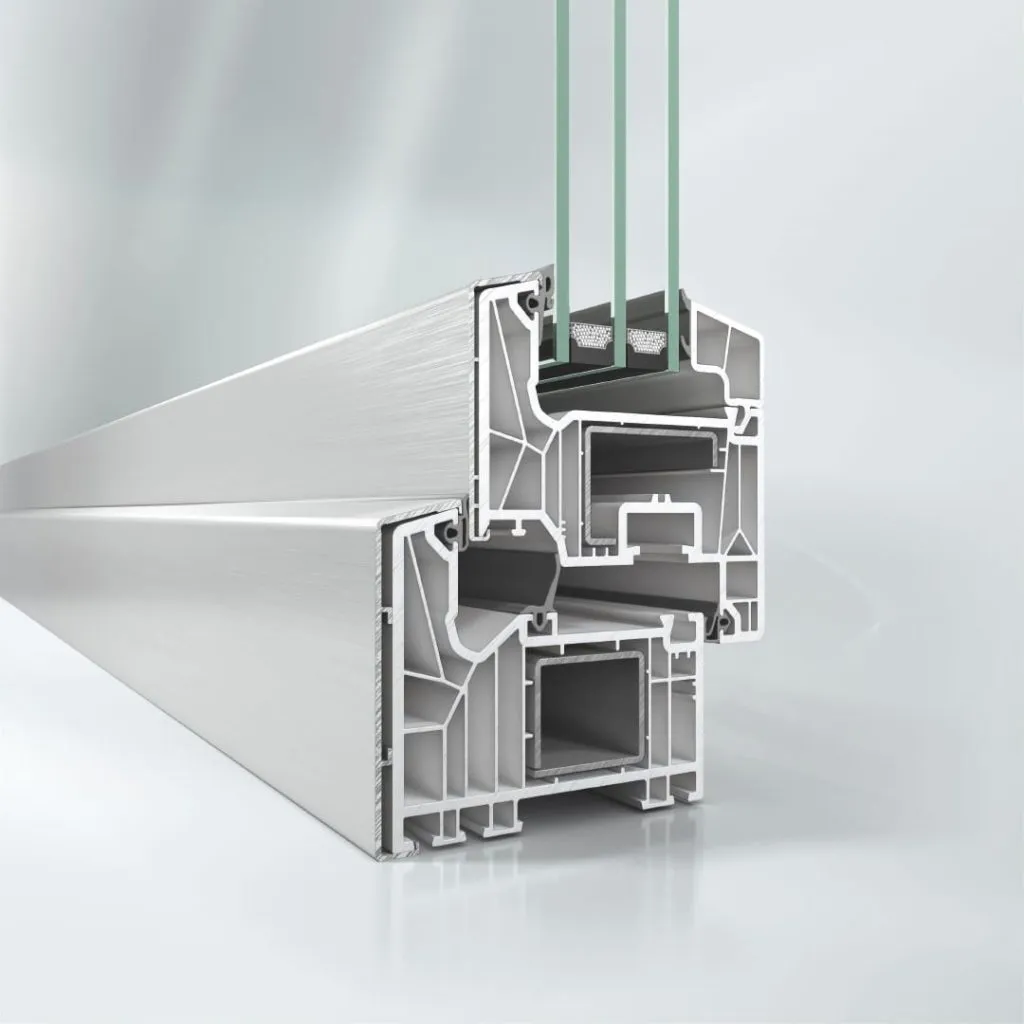

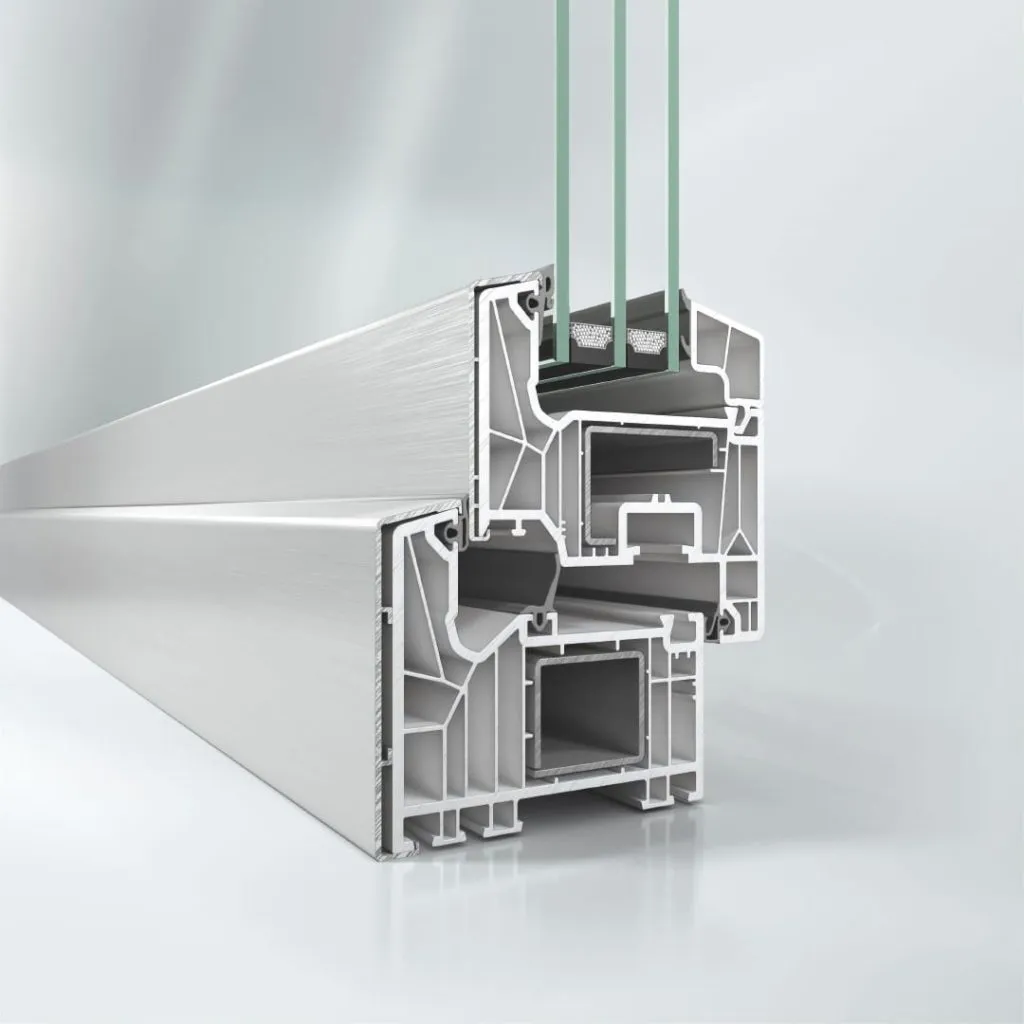

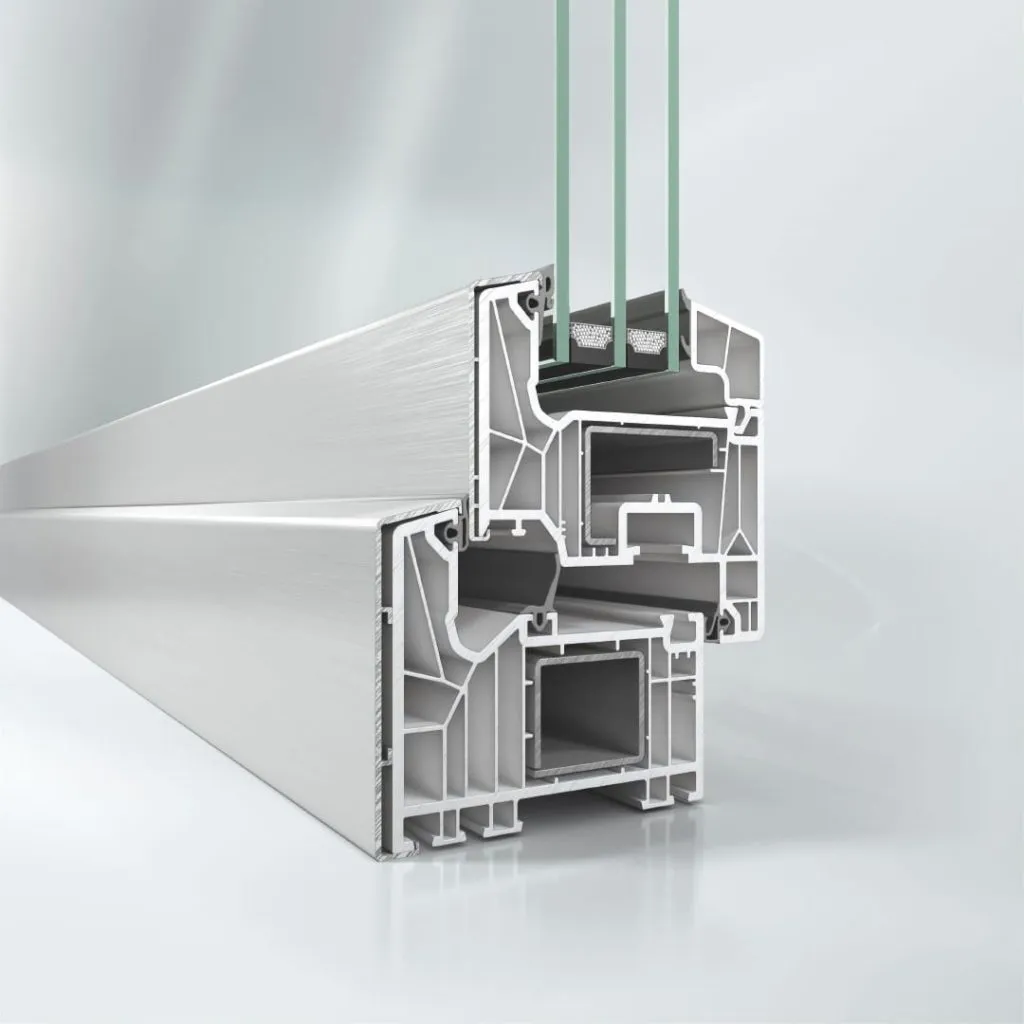

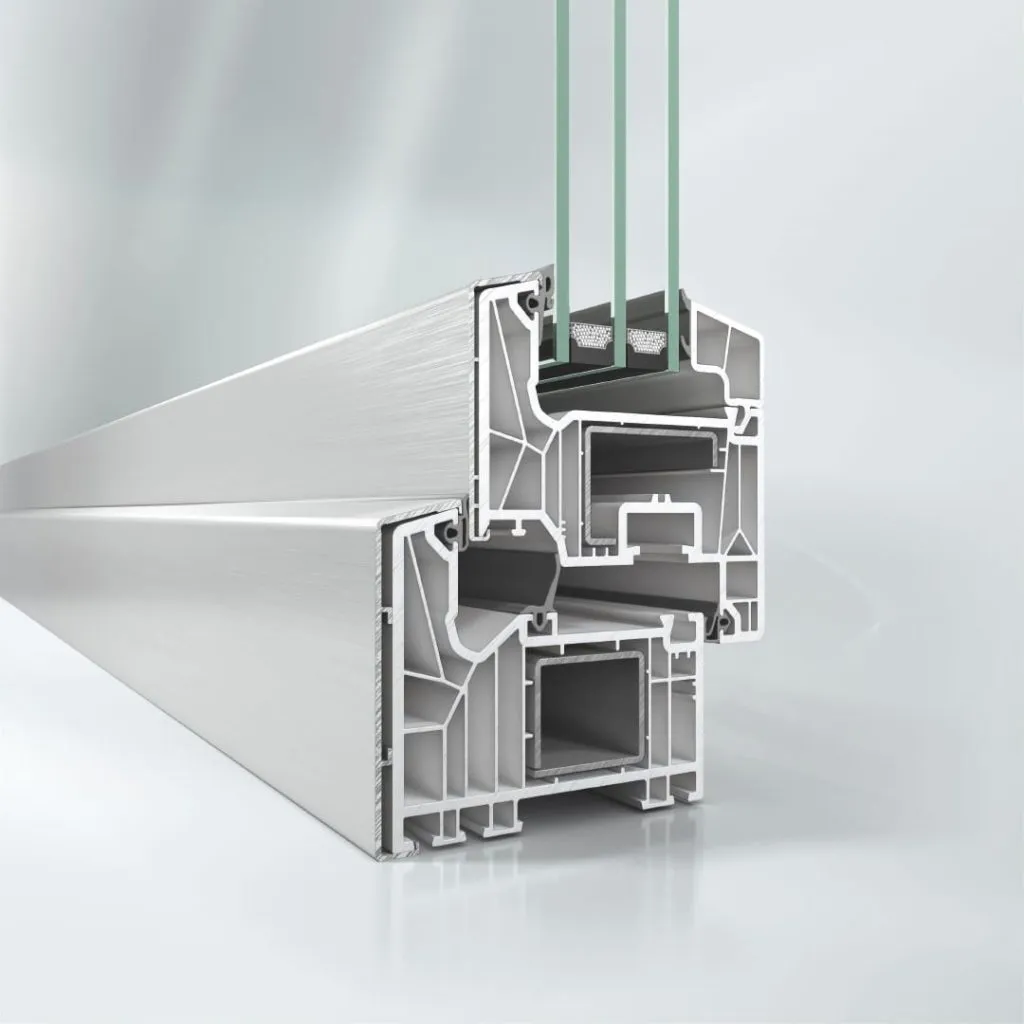

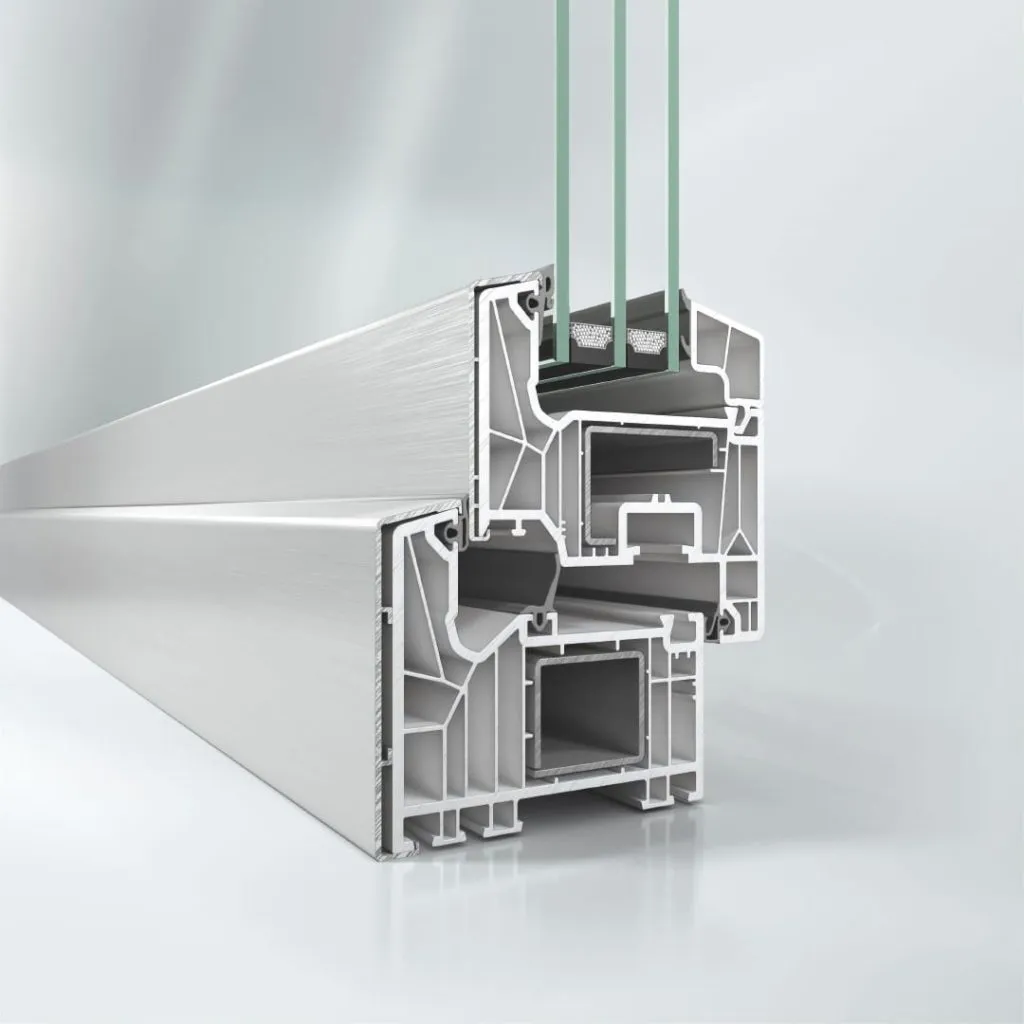

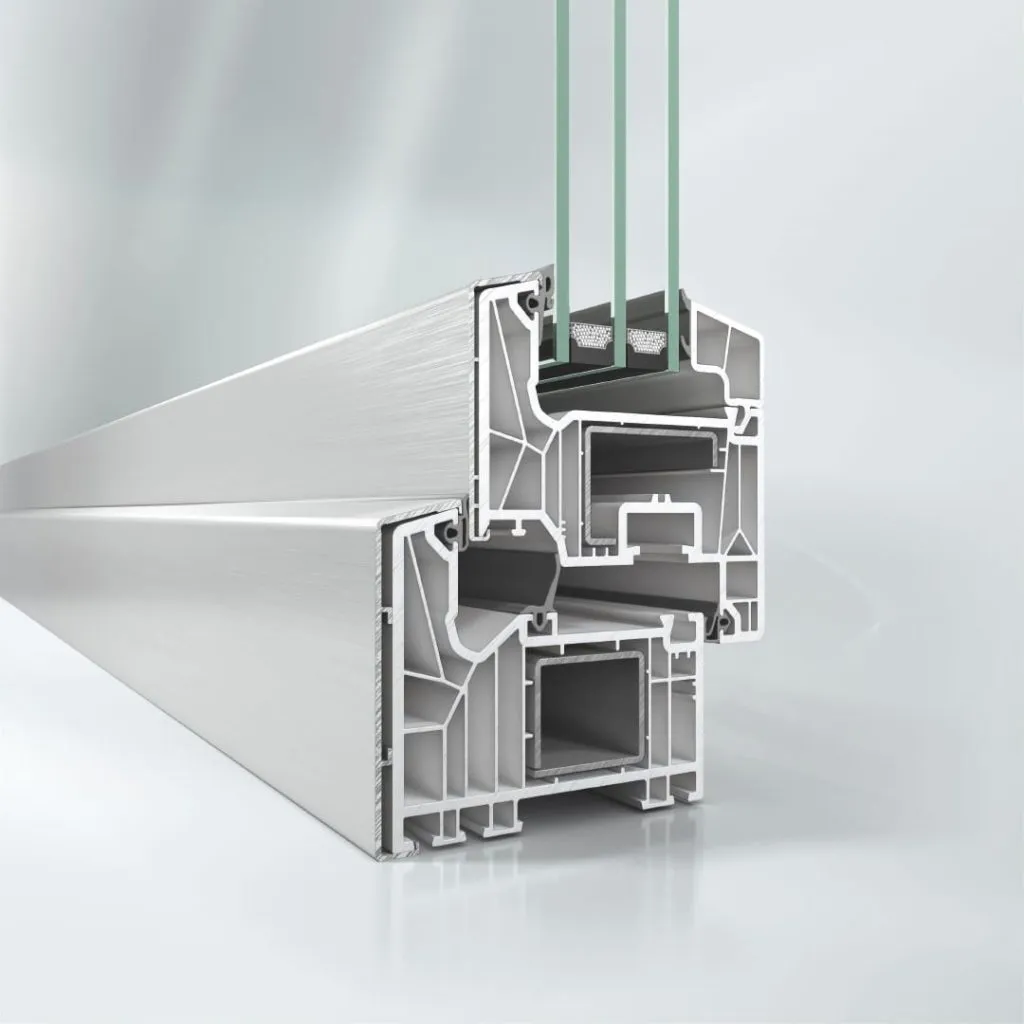

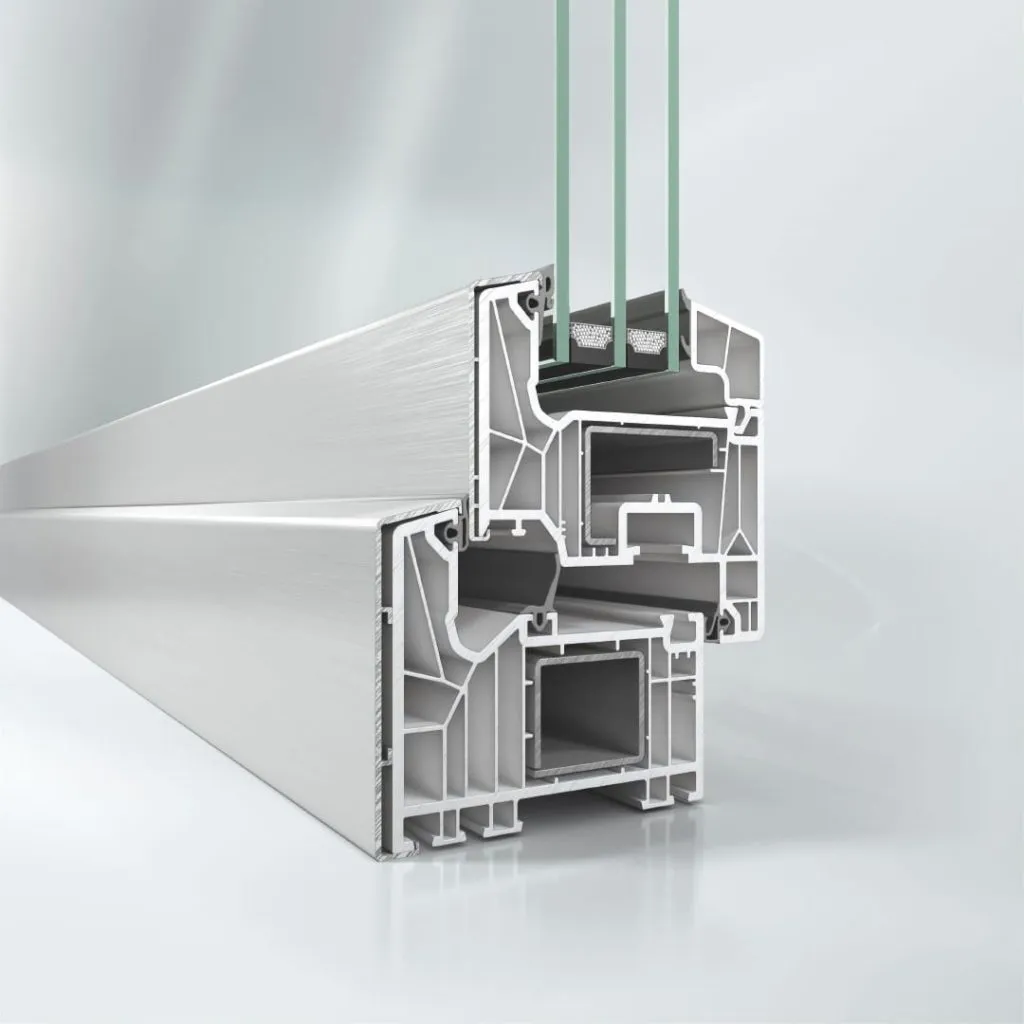

Aliplast Imperial

- The Imperial system with enhanced thermal insulation: IP i, IP i+, designed for constructing windows, doors, and storefronts with high thermal insulation performance.

- High thermal insulation parameters are achieved through the use of special thermal inserts placed between thermal breaks and around the glass.

- A wide range of system profiles ensures the required aesthetics and structural durability.

- Windows can be installed within façade systems.

- Glazing beads available in rectangular and rounded variants.

- The broad glazing range allows for the use of all common glass types: single, double-chamber, acoustic, or burglar-resistant.

- Profile drainage is available in two options: traditional or concealed.

- The system is designed for use in residential and public utility buildings and allows for modern window structure designs in multiple variants.

- The construction of the IPi and IPi+ systems is based on the well-proven, well-developed, and highly regarded Imperial base system.

- FRAME DEPTH – 2.56 in

- GLAZING THICKNESS – 0.16-2.01 in

- THERMAL INSULATION UF* – Uf from 0.276 BTU/(h·ft²·°F)

- AIR PERMEABILITY – Class 4; standard PN-EN 12207

- WIND LOAD RESISTANCE – Class C4; standard PN-EN 12210

- WATER TIGHTNESS – Class E1350; standard PN-EN 12208

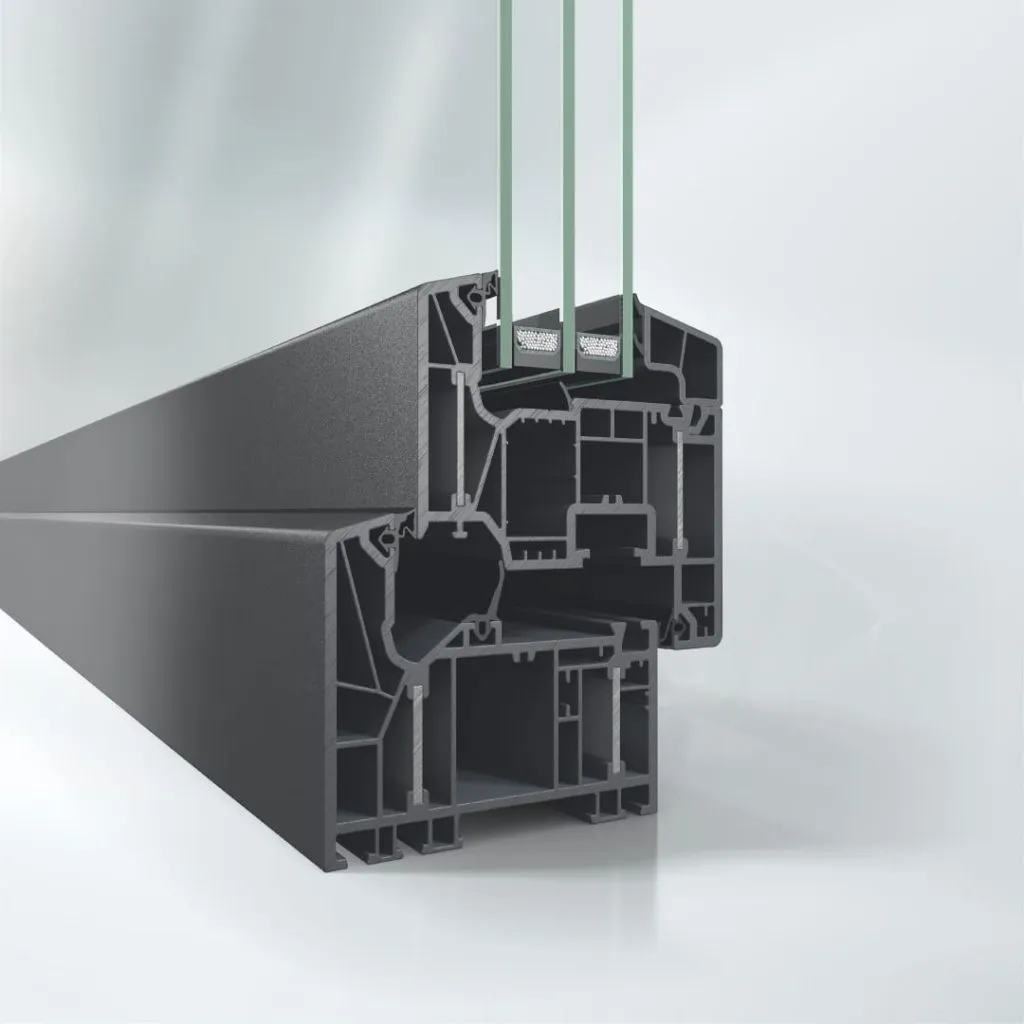

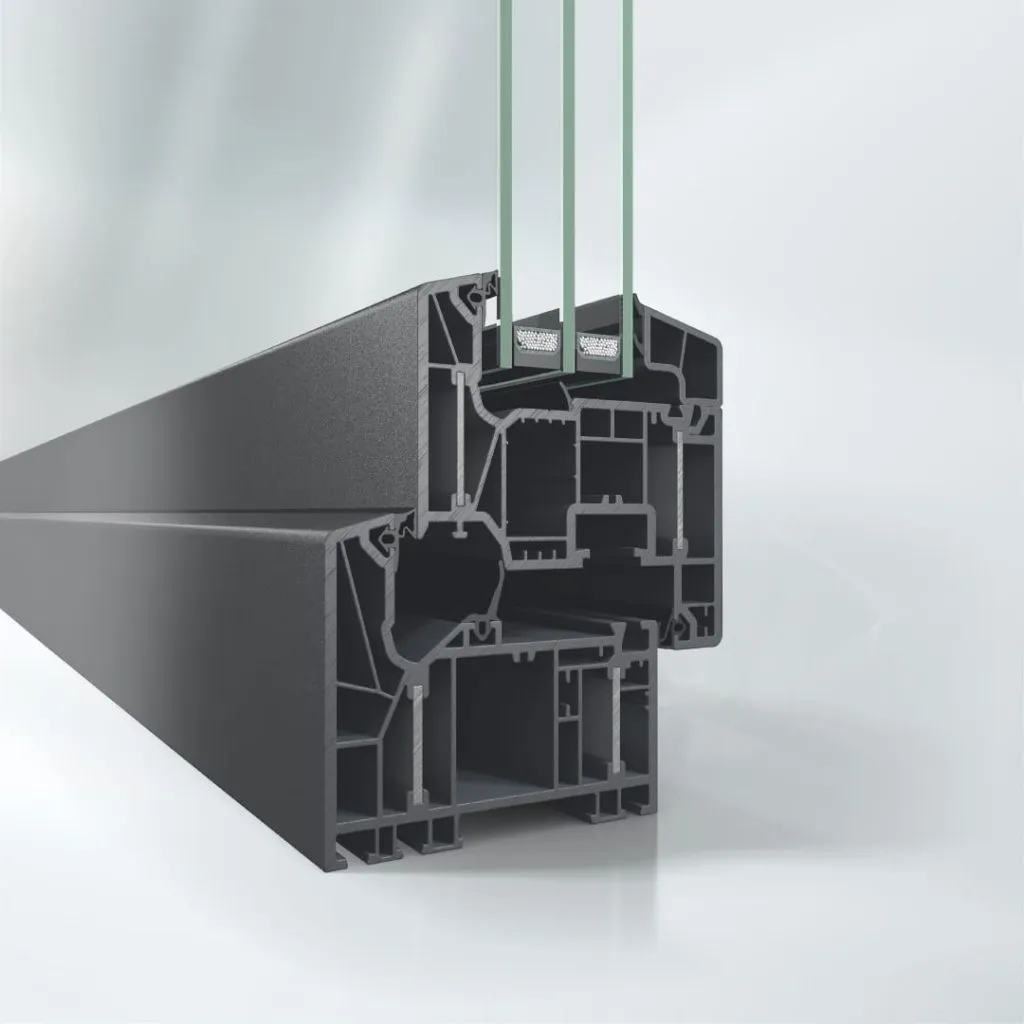

Aliplast Steel Look

- A thermally insulated window and door system characterized by a smooth and slim profile design.

- The unique profile shape (resembling steel profiles) gives the structure an industrial, modern look.

- Steel Look is a system that stands out in the market with its unique design.

- FRAME DEPTH – 3.54 in

- GLAZING THICKNESS – 0.20-1.69 in

- THERMAL INSULATION UF* – Uf from 0.199 BTU/(h·ft²·°F)

- AIR PERMEABILITY – Class 4; standard PN-EN 12207

- WIND LOAD RESISTANCE – C4 (23.21 psi); standard PN-EN 12210

- WATER TIGHTNESS – 9A; standard PN-EN 12208

Aliplast – Ultraglide

- A high thermal insulation system designed for sliding or lift-and-slide structures.

- UG sliding constructions are intended for use in residential buildings, primarily individual housing, as well as public utility buildings.

- The system is adapted to the latest requirements in thermal insulation, aesthetics, and safety, with available options including:

- UG version with a low threshold

- UG – 90° corner solution

- Thanks to its parameters, the ULTRAGLIDE system allows for the design of large sliding sash structures: the maximum achievable dimensions in this system are a sash height of Hs = 129.92 in and a sash width of Bs = 137.80 in.

- The ULTRAGLIDE system enables the construction of large yet stable sliding windows and doors, with a maximum sash weight of 551 lbs for the sliding option and 881.85 lbs for the lift-and-slide option.

- Frame construction: 3-, 5-, and 7-chamber system

- Possible two-, three-, and four-element combinations based on a dual-track system.

- Profiles are adapted for the installation of various locking hardware available on the market, both manual and automated.

- Compatible with different types of infills (single and double-glazed units).

- The system meets the latest thermal insulation requirements, featuring a thermal break with widths of 0.87 in and 1.10 in reinforced with fiberglass, as well as thermal inserts and under-glass inserts to enhance cross-sectional insulation.

- Available options: UG, UGi, UG i+ versions.

- The system allows for the construction of large glazed areas, ensuring excellent interior lighting while maintaining stability, functionality, and a lightweight design.

- FRAME DEPTH – From 6.02 in to 9.41 in

- GLAZING THICKNESS – 0.55-2.05 in

- THERMAL INSULATION UF* – Uf from 0.199 BTU/(h·ft²·°F)

- AIR PERMEABILITY – Class 4; standard PN-EN 12207

- WIND LOAD RESISTANCE – C4 (23.21 psi); standard PN-EN 12210

- WATER TIGHTNESS – 9A; standard PN-EN 12208

Aliplast Visoglide

- A three-chamber system designed for sliding door construction.

- Thermally insulated system (thermal breaks made of high-insulation material).

- System options: sliding and lift-and-slide; Monorail solution available.

- Extremely narrow interlock mullion in sliding and lift-and-slide sashes – width of 1.34 in.

- Possible two-, three-, four-, and six-element combinations based on a two- or three-track frame.

- Compatible with the Flyscreen system (mosquito screen system for insect protection).

- FRAME DEPTH – 4.65/5.59/7.24 in

- GLAZING THICKNESS – 0.24-1.42 in; Monorail option: 0.71–2.36 in

- THERMAL INSULATION UF* – Uf from 0.370 BTU/(h·ft²·°F)

- AIR PERMEABILITY – Class 4; standard PN-EN 12207

- WIND LOAD RESISTANCE – C3/B4 (17.41 psi); standard PN-EN 12210

- WATER TIGHTNESS – 9A; standard PN-EN 12208